EPC Releases Phase 14 Report on GaN Reliability and the Use of Physics-Based Models to Project eGaN® Device Lifetime

EPC Releases Phase 14 Report on GaN Reliability and the Use of Physics-Based Models to Project eGaN® Device Lifetime

Efficient Power Conversion (EPC) publishes Phase-14 Reliability Report, which adds to the extensive knowledge and demonstrates a robustness capability unmatched by silicon power devices.

EL SEGUNDO, Calif.--(BUSINESS WIRE)--EPC announces its Phase-14 Reliability Report, documenting the strategy used to achieve a remarkable field reliability record. The rapid adoption of GaN devices in diverse applications calls for the continued accumulation of reliability statistics and research into the fundamental physics of failure in GaN devices. The Phase-14 Reliability Report presents the strategy used to measure and predict lifetime based upon tests that force devices to fail under various conditions. This information can be used to create more robust and higher performance products for applications such as lidar for autonomous cars, robotics, security, drones, high power density computing, and satellites, to name just a few.

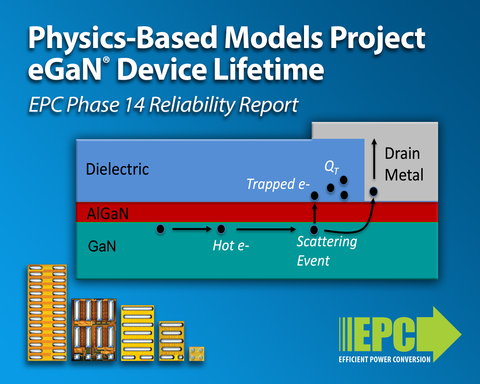

This report presents the results of testing eGaN devices to the point of failure, which provides the information to identify intrinsic failure mechanisms of the devices. By identifying these intrinsic failure mechanisms, deep knowledge of the behavior of a device over time, temperature, electrical or mechanical stress can be developed and used to create physics-based models that accurately project the safe operating life of a product over a more broad set of operating conditions.

This report is divided into eight sections, each dealing with a different failure mechanism:

Section 1: Intrinsic failure mechanisms impacting the gate electrode of eGaN devices

Section 2: Intrinsic mechanisms underlying dynamic RDS(on)

Section 3: Applying the physics-based model to common real-world use cases

Section 4: Safe operating area (SOA)

Section 5: Testing devices to destruction under short-circuit conditions

Section 6: Custom test to assess reliability over long-term lidar pulse stress conditions

Section 7: Mechanical force stress testing

Section 8: Thermo-mechanical stress

According to Dr. Alex Lidow, CEO and co-founder of EPC, “The release of EPC’s Phase-14 reliability report represents the cumulative experience of millions of devices and five generations of technology to lead to a deeper understanding of the behavior of GaN devices over a wide range of stress conditions.”

About EPC

EPC is the leader in enhancement mode gallium nitride (eGaN®) based power management. eGaN FETs and integrated circuits provide performance many times greater than the best silicon power MOSFETs in applications such as DC-DC converters, remote sensing technology (lidar), motor drives for eMobility, robotics, and drones, and low-cost satellites.

Visit our website: www.epc-co.com

Follow EPC on social media: LinkedIn, YouTube, Facebook, Twitter, Instagram, YouKu

eGaN is a registered trademark of Efficient Power Conversion Corporation, Inc.

Contacts

Efficient Power Conversion: Renee Yawger tel: +1.908.619.9678 email: renee.yawger@epc-co.com