Wright Electric Launches Battery Program Targeting 1,000 wh/kg Pack Density

Wright Electric Launches Battery Program Targeting 1,000 wh/kg Pack Density

- 4x lighter than today’s lithium ion

- Designed to enable electrification of 100 passenger electric aircraft as well as trucking, shipping, and rail

- Paradigm shift in transportation decarbonization

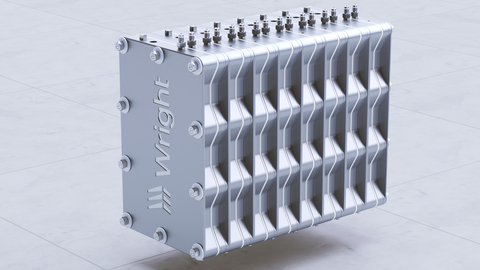

ALBANY, N.Y.--(BUSINESS WIRE)--Today, Wright Electric, a world leader in electric propulsion systems for regional aircraft, launched Wright Batteries, an initiative to develop batteries targeting 1,000 watt hours per kilogram (wh/kg) pack density.

“When I founded Wright, the best vehicle batteries had an energy density below 250 wh/kg,” said Jeff Engler, CEO of Wright. “Now several large manufacturers are advertising cells at double that capacity, and we have visibility into new battery chemistries that could get us to our target of 1,000 wh/kg.”

Wright’s proprietary batteries would be 4x more energy dense than the lithium ion batteries that power today’s electric vehicles. Such batteries would enable the electrification of hard-to-decarbonize transportation and mining sectors, for example electric aircraft with 100 passengers. Given that the vast majority of aerospace carbon emissions are in aircraft with 100 or more passengers, these batteries would enable a paradigm shift in decarbonization.

Founded in 2016, Wright’s goal is to decarbonize the aerospace industry. Wright works with leading groups such as easyJet, NASA, Y Combinator, The US Department of Energy Advanced Research Projects Agency–Energy, and the US Department of Defense.

Wright has built power dense electric motors, inverters, and generators for aerospace and defense applications. For example, Wright recently tested its industry-leading electric motor to 1 megawatt and is planning for altitude testing at the NASA Electric Aircraft Testbed (NEAT).

Building on this work, Wright is now applying its expertise in lightweight mechanical and electrical systems to battery development. Since 2021, Wright has been conducting experiments with battery technologies that have been overlooked by conventional battery manufacturers. Some battery types are unsuitable for consumer electronics or grid storage, however they could be ideal for applications that require extreme light weight, safety, and compactness.

“We have developed experience building lightweight thermally managed electric propulsion systems, and we see a way to apply that knowledge to the design of large molten battery packs,” says Colin Tschida, Head of Powertrain at Wright.

“To cultivate a breakthrough in energy storage, we engaged four chemistry PhDs to act as scouts for promising battery chemistries,” said Tschida. “This month, we are beginning our second phase of validation experiments with the approaches that showed the most promise.”

Wright is working with multiple academic centers and industry partners to achieve these batteries. Initial packs will be released for laboratory testing in 2025 with first rollout to aerospace and defense early adopters targeted for 2027.

For additional information, please contact Elizabeth Wallace at elizabeth.wallace@weflywright.com.

Wright Electric is a U.S.-based company building electric aircraft, energy storage, and power generation solutions for the aerospace and defense industries. Wright works with NASA, DOE, and DoD. Please visit https://www.weflywright.com/ for more information.

Contacts

Elizabeth Wallace at elizabeth.wallace@weflywright.com