Graforce presents plasma electrolysers for hydrogen from methane and wastewater on IFAT 2022 fair

Graforce presents plasma electrolysers for hydrogen from methane and wastewater on IFAT 2022 fair

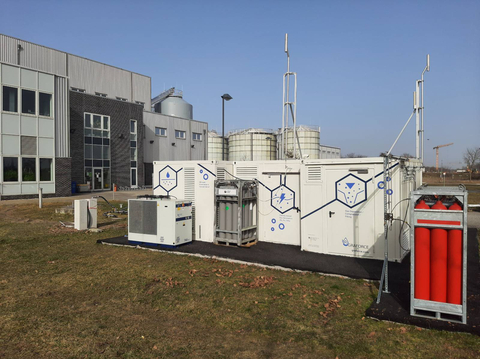

BERLIN--(BUSINESS WIRE)--Green hydrogen is key to achieving a circular economy. Graforce has developed a plasma electrolysis technology that can produce hydrogen from residual materials – with significantly lower manufacturing costs and higher yields. Graforce will be demonstrating its marketable methane and wastewater electrolysis plants and refueling systems at IFAT, the world’s leading trade fair for water, sewage and waste management. They demonstrate the immense market potential of green hydrogen and the range of applications for CO2-free or even CO2-negative energy and fuel.

Green hydrogen is projected to have a game changing impact in the mobility, industry, and decentralized energy segments. It plays an important role in meeting global climate goals. The global hydrogen market is forecast to grow by a factor of 6 by 2050. Germany makes up 20 percent of the current European hydrogen consumption and is also forecast to remain the largest hydrogen off-take market in the EU, driven by strong decarbonization commitments across sectors.

The production of hydrogen using plasma electrolysis requires considerably less energy than water electrolysis and leads to significant cost reductions. Whereas water electrolysis needs 50kWh/kg H2, the production of 1kg hydrogen from methane takes only 10kWh or 20kWh from wastewater.

“Whether as fuel, heat source or a raw material, green hydrogen can make a significant contribution to achieving climate targets in many industries,” explains Dr. Jens Hanke. “Our plants produce green hydrogen from methane, wastewater, liquid manure or ammonia. We thus close energy and material cycles and make a significant contribution to a future without fossil fuels and CO2 emissions. And we deliver this quickly and cost-effectively."

For the development and customer-specific scaling of its modular plants, Graforce works with global leaders in the fields of engineering, procurement, and construction. The company is currently in the process of expanding its strategic partnerships with financial as well as strategic investors to quickly scale its technology worldwide.

About

The German company Graforce is a technology leader in sustainable solutions and carbon dioxide removal technologies. The power-to-X plants produce CO2-free or CO2-negative hydrogen and synthetic feedstocks – with the highest efficiency and lower infrastructure costs in the multi-megawatt range. Thus, Graforce decarbonizes fossil energies, industrial sectors and the heat, transport and building sectors. www.graforce.com/EN

Contacts

Graforce GmbH

Dr. Jens Hanke

Phone: +49 30 - 63 2222-110

presse@graforce.de