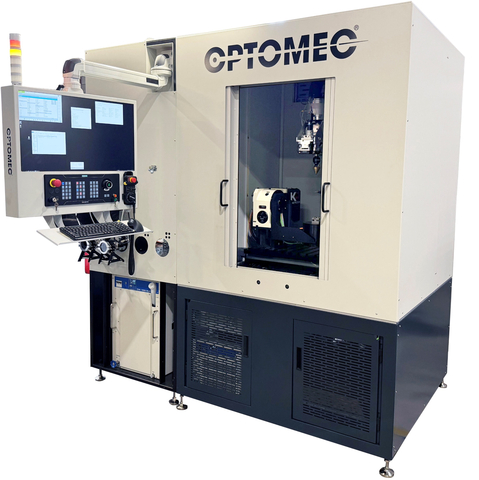

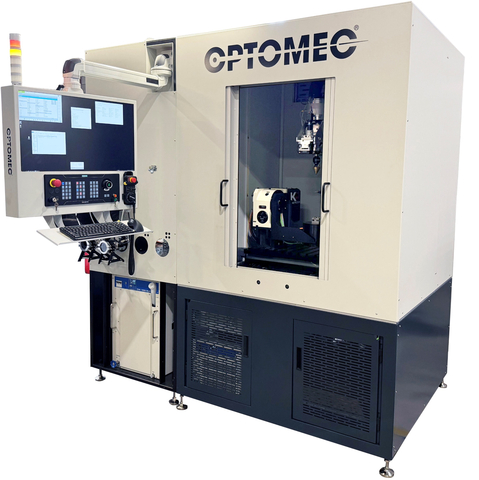

ALBUQUERQUE, N.M.--(BUSINESS WIRE)--Optomec, a leading supplier of digital manufacturing hardware and software, and Siemens, a global leader in technology for industrial automation hardware, digitization software and services, today announced a next generation solution for laser cladding of high value metal repair in production environments using additive manufacturing. Unlike conventional systems that are labor intensive and skill dependent, the joint solution integrates the Optomec CS 558 system and Siemens SINUMERIK ONE to deliver advanced hardware and software that automates and simplifies maintenance, repair, and overhaul (MRO) operations for increased productivity and cost savings.

According to Grand View Research, the global laser cladding market in 2023 is estimated at USD $561.3 million and projected to grow at a CAGR of 9.3 percent from 2024 to 2030. Additive manufacturing technology such as directed energy deposition (DED) used by CS 558 expands laser cladding fabrication capabilities to repair complex components with mixed materials on various substrates to enhance performance, longevity and reliability. Combined with Optomec’s vision software, Autoclad®, that generates a custom toolpath for each part prior to processing, manufacturers and servicers of high value metal parts can restore worn or damaged components and use automated DED to repair reactive metals like titanium in a controlled environment. SINUMERIK ONE adds high performance CNC to deliver maximum speed and path precision when machining free form surfaces and fluid operation in high load scenarios. Along with its digital twin, the SINUMERIK ONE digital native control provides the basis for future-oriented production with machine tools.

Industry applications for the joint solution include aerospace, automotive, oil and gas, marine, medical and semiconductor/electronics.

“Optomec and Siemens are introducing a transformative solution for the MRO of high value metals in production environments that is a paradigm shift for the industry,” said Robert Yusin, CEO of Optomec. “This is a next generation solution that maximizes efficiency, minimizes operational complexity and greatly reduces time to ROI for customers."

“Our collaboration with Optomec represents a significant leap forward in industrial automation and additive manufacturing," said Steve Vosmik, Head of Additive Manufacturing, US at Siemens. "By integrating SINUMERIK ONE with Optomec’s advanced CS 558 platform, we are delivering a solution that simplifies complex repair processes with unprecedented precision and efficiency. This not only addresses current industry demands but also sets a new benchmark for the future of high-value metal repair in sectors like aerospace and energy."

ADDITIONAL RESOURCES

- Watch a video on directed energy deposition (DED) technology used for additive manufacturing in Optomec systems.

- Read a technical whitepaper on the repair of aircraft engine blades using automated laser cladding and additive manufacturing.

- Watch a video on additive manufacturing for aircraft engine blade repair.

About Optomec

Optomec is a leading supplier of Digital Manufacturing hardware and software. Optomec’s patented Aerosol Jet Systems for fine feature printing, and LENS® and Huffman brand 3D Printers for metal component production and repair, are used by many industries to reduce product cost and improve performance. Together, these unique printing solutions work with the broadest spectrum of functional materials, ranging from electronic inks to structural metals and even biological matter. Optomec has delivered more than 600 of its proprietary Digital Manufacturing systems to more than 200 marquee customers around the world, for production applications in the electronics, energy, life sciences and aerospace industries. Notable customers include GE, Samsung, Raytheon, Siemens, Corning, Lockheed Martin, the US Air Force, US Navy, US Army and NASA. For more information, visit optomec.com.

LENS is a registered trademark of Sandia National Labs; Aerosol Jet is a registered trademark of Optomec, Inc.

About Siemens

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

Siemens Corporation is a U.S. subsidiary of Siemens AG, a technology company focused on industry, infrastructure, transport, and healthcare. From more resource-efficient factories, resilient supply chains, and smarter buildings and grids, to cleaner and more comfortable transportation as well as advanced healthcare, the company creates technology with purpose adding real value for customers. By combining the real and the digital worlds, Siemens empowers its customers to transform their industries and markets, helping them to transform the everyday for billions of people. Siemens also owns a majority stake in the publicly listed company Siemens Healthineers, a globally leading medical technology provider shaping the future of healthcare. In addition, Siemens holds a minority stake in Siemens Energy, a global leader in the transmission and generation of electrical power. In fiscal 2022, which ended on September 30, 2022, Siemens Group USA generated revenue of $18.6 billion and employs approximately 45,000 people serving customers in all 50 states and Puerto Rico.