BERGEN OP ZOOM, Netherlands--(BUSINESS WIRE)--Over the next three years, 11 partners in West-North Brabant, led by TNO, will be working together to make green building blocks with local tree and plant residues. Westlake Epoxy plays a key role in project Consortium B4, aiming to explore the replacement of fossil fuel-based feedstock with a bio-based feedstock for the production of epoxy resins. In collaboration with consortium partners, these novel bio-based feedstocks are tested and tailored to meet the specific requirements for producing epoxy resins and ensuring the epoxy product meets customer’s product properties requirements.

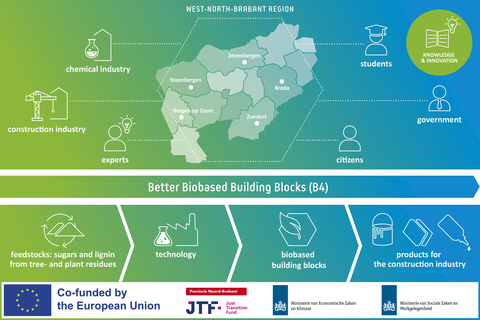

From grass to glue, from sugar beet pulp to paint or from wood chips to insulation foam are examples of what the B4 project – Better Bio-based Building Blocks - envisions. These building blocks not only make products for the construction industry more sustainable, but also provide scratch resistance, flame retardancy or ultraviolet (UV) resistance. Besides these technological innovations, the partners in this B4 project also share knowledge with students, companies and governments to prepare them for and involve them in this raw materials transition. This will transform Western North Brabant, a province in the south of the Netherlands, into a hotspot for bio-based building blocks for the construction industry.

The construction sector faces a huge challenge: to cut CO2 emissions by half by 2030 and 90% by 2050. One of the fossil building blocks that are going to be replaced by a sustainable alternative are aromatics. As much as 40% of all products around us contain aromatics. Think of paint, glue, insulation materials, textiles and foams. Currently, aromatics are made from fossil raw materials, and this is not beneficial for our climate.

B4: Better Bio-based Building Blocks

The B4 project combines the entrepreneurship, knowledge and expertise of small and medium-sized companies (Relement, Impershield, Baril Coatings, Bodewes and Progression-Industry) and larger companies (Westlake Epoxy and Worlée) with the technologies and knowledge of TNO, VITO and Avans University of Applied Sciences. The partners want to show that bio-based aromatics can successfully replace fossil aromatics in at least six applications for the construction industry, such as coatings, composites, acrylic and epoxy resins. And that these non-fossil alternatives are not only more sustainable, but also commercially attractive.

Green Chemistry Campus as epicenter

The Green Chemistry Campus in Bergen op Zoom is the epicenter of this project. It is home to Shared Research Center Biorizon, an initiative of TNO and VITO that is working with partners on the technological development of bio-aromatics.

By the inclusion of all stakeholders a flywheel will be created that will make the transition to a climate-neutral economy a reality. Within the B4 project, the Campus therefore organizes many meetings and workshops for a broad audience. For SMEs who want to know what the opportunities are for their company, for students considering a career in bio-based chemistry, for employees in the chemical industry who want to know what will change for them when they start working with bio-based raw materials, and for governments who want to know what the opportunities of this raw material transition are for their organization.

West-North Brabant as bio-based hotspot

Helping regions that rely heavily on fossil-based industries with the transition to a climate-neutral economy in a just and equitable way; that is the goal of the European Union's Just Transition Fund. The B4 project aims to make Western North Brabant a hotspot for bio-based building blocks for the construction sector. West-North Brabant potentially has everything to realize this goal: residual agricultural products such as sugar beet pulp as green raw material, a chemical sector with a lot of knowledge and personnel and strong logistical connections. The B4 project partners want to offer sustainable economic prospects to the region by providing a new earnings model for the agricultural sector and creating additional jobs in the chemical industry.

The B4 project has a total budget of €4.4 million and it is co-financed by the European Union under the Just Transition Fund (JTF), the Ministry of Economic Affairs and Climate Policy, the Ministry of Social Affairs and Employment and the Province of North Brabant.

Contact

For more information about the B4 project, please contact project leader Paul Könst at paul.konst@tno.nl or +31 (0)6 25 04 13 79.

About Westlake

Westlake Corporation (NYSE: WLK) is a global manufacturer and supplier of materials and innovative products that enhance life every day. Headquartered in Houston, with operations in Asia, Europe, and North America, we provide the building blocks for vital solutions — from housing and construction, to packaging and healthcare, to automotive and consumer. For more information, visit the company's web site at www.westlake.com.