How AI is Driving Nissan’s Cutting-Edge Paint Process Toward Perfection

How AI is Driving Nissan’s Cutting-Edge Paint Process Toward Perfection

Nissan uses artificial intelligence and machine learning to quickly identify and correct paint flaws on new vehicles

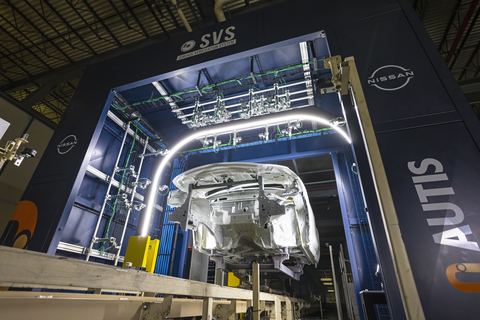

When it comes to paint, it’s often what you don’t notice that provides an impression of quality. Smooth, consistent coverage makes a Nissan shine – whether it’s an Electric Blue Metallic Sentra or a Baja Storm Metallic Rogue. Nissan uses nearly two gallons of paint on each vehicle during the manufacturing process. And with three coats (prime, base and clear), there can be opportunities for imperfections to form on the surface – even in the most sterile environment. (Photo: Business Wire)

NASHVILLE, Tenn.--(BUSINESS WIRE)--When it comes to paint, it’s often what you don’t notice that provides an impression of quality. Smooth, consistent coverage makes a Nissan shine – whether it’s an Electric Blue Metallic Sentra or a Baja Storm Metallic Rogue.

Nissan uses nearly two gallons of paint on each vehicle during the manufacturing process. And with three coats (prime, base and clear), there can be opportunities for imperfections to form on the surface – even in the most sterile environment.

To combat this, Nissan has invested in advanced artificial intelligence (AI) and machine learning to detect paint flaws faster than ever.

Using the AUTIS Surface Verification System, Nissan has improved its defect detection rate by nearly 7% at its Smyrna, Tennessee assembly plant.

AUTIS uses high-resolution cameras to capture 15,000 pictures of each vehicle immediately after it is painted. These images are analyzed to detect possible defects.

“The human eye can spot 85%-95% of flaws, but AUTIS identifies over 98%,” said Travis Fritsche, a paint process engineer at Nissan.

When AUTIS flags a potential blemish, technicians can review the imperfections instantly on monitors and wrist-worn, company-owned smartphones specifically used for the inspection process. This process reduces eye fatigue while increasing the amount of time available to carefully correct the paint.

“Technicians are critical for confirming and categorizing defects. AUTIS is a tool to enhance their work, not replace it,” said Rod Lynch, a new model paint engineer at Nissan.

Added Fritsche: “AUTIS has significantly reduced our investigation time and elevated our quality.”

Leveraging machine learning to power continuous improvement

Since AUTIS was first implemented nearly three years ago, it has evaluated over 500,000 Nissan vehicles at the Smyrna Vehicle Assembly Plant alone. It is also in use at Nissan plants in Canton, Mississippi. and Aguascalientes, Mexico, covering vehicles models like Altima, Frontier, LEAF, Pathfinder, Rogue, Kicks, Sentra, Versa and Murano.

With machine learning, AUTIS is constantly refining its detection capabilities.

“It’s a self-learning system,” said Lynch. “With feedback from technicians, AUTIS learns to recognize defects like dirt, fibers and craters. It will continue to learn and refine and will build a library of what defects look like.”

This growing defect library not only helps identify flaws faster but also assists the team in addressing process issues, which are categorized by vehicle type and color.

“AUTIS can group defects to help pinpoint patterns and improve our processes,” Fritsche said.

Nissan has been on the cutting edge of paint inspection technology for decades. In 1985, Nissan became the first auto manufacturer to use laser-equipped robots to perform paint inspections, detecting imperfections as small as 0.3 millimeters in 45 seconds. Today, AUTIS can find imperfections as tiny as 0.2 millimeters in less than half the time, representing nearly four decades of technological progress.

While paint covers the surface of a vehicle, Nissan’s commitment to quality runs much deeper. By combining human expertise with cutting-edge AI, Nissan delivers vehicles that meet the highest standards of craftsmanship.

About Nissan USA Stories

The Nissan USA Stories page explores the best of Nissan’s people, products, technology and more. New to the page? Subscribe here to receive alerts when a new story is published.

Contacts

Eric Ruble

Sr. Specialist, Technology & Safety Communications

Eric.Ruble@nissan-usa.com