LOUISVILLE, Colo.--(BUSINESS WIRE)--Sierra Space, a leading commercial space company and defense tech prime that is Building a Platform in Space to Benefit Life on Earth®, announced today the company’s proprietary Carbothermal Oxygen Production Reactor has successfully completed thermal vacuum testing at NASA’s Johnson Space Center, heralding the first time in history that oxygen has been extracted from simulated lunar soil, or regolith, using an automated, standalone system in a lunar environment. The technology, when scaled up, is designed to produce oxygen in bulk to support one of the primary objectives of NASA’s Artemis program: establishing the first long-term presence on the moon.

“The Apollo program took us to the moon to study and learn. Artemis is taking us back to the moon, this time to stay,” said Tom Vice, CEO of Sierra Space. “Our company is focused on building the infrastructure necessary to enable continuous human presence on the lunar surface. This sustainable future begins with developing the core technology and systems that create oxygen in that environment, using local natural resources.”

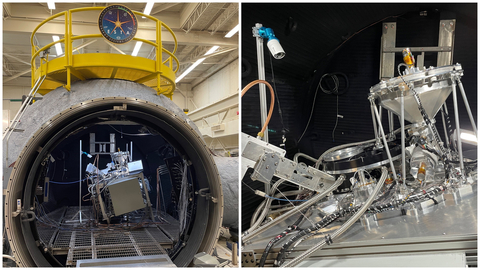

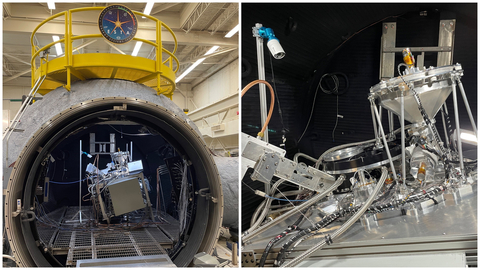

Sierra Space test engineers spent two weeks in August operating the company’s oxygen extraction system inside a thermal vacuum chamber at Johnson, working with lunar regolith simulant in an environment the hardware would recognize as similar to the water-ice-laden south pole region of the moon. Under lunar temperatures and pressures, the Sierra Space system executed all of the regolith handling steps and performed the carbothermal reduction reaction that extracts oxygen from minerals in the regolith simulant.

This disruptive innovation, a system developed at Sierra Space’s facilities in Madison, Wisconsin, represents a major leap forward in enabling long-term human habitation on the moon and future space exploration endeavors. The company’s Destinations and In-Space Infrastructure team, known for their work in building the world’s first commercial LEO space station, is leveraging the company’s pioneering technologies in large expandable space modules, environmental control systems and in-space food growth systems, to build core infrastructure on the moon.

“This latest testing validates that the technologies and techniques developed and employed in the Sierra Space oxygen extraction system would work on the lunar surface,” said Shawn Buckley, Vice President of Space Destinations Systems at Sierra Space. “These efforts confirmed that the hardware has advanced to Technology Readiness Level Six, or TRL-6, meaning it has the maturation to be incorporated into a flight mission to the moon as a technology demonstrator.”

Temperatures in which the Sierra Space Carbothermal Oxygen Production Reactor were tested ranged from minus 45 degrees Celsius to 1,800 degrees Celsius. In addition to the challenges of functioning from sub-zero to hotter-than-lava temperatures, the hardware was required to move the simulated lunar regolith – a very abrasive and jagged material because it does not have the weathering processes found on Earth – through its system. The potentially damaging particles were handled effectively by the hardware and gasses were successfully sealed inside the reactor, thanks to Sierra Space’s use of a patent-pending valve design that previously demonstrated functionality to greater than 10,000 cycles.

The tests confirmed that Sierra Space’s system can successfully handle regolith that would be delivered from a lunar rover or robotic arm and automatically bring it into the reaction chamber, perform the carbothermal reduction reaction process to extract the oxygen from the minerals in the regolith, and remove the processed regolith from the system so the operation can be repeated.

“By harnessing the natural resources found on the moon, we reduce our reliance on Earth-based supplies and open up new frontiers for space exploration and commercialization,” Vice added. “With our breakthrough technology that can provide a reliable source of oxygen in-situ, Sierra Space is poised to play a potential role in NASA’s Artemis program and other initiatives aimed at establishing a permanent human presence on the lunar surface.”

Resources like oxygen are crucial building blocks; in addition to using oxygen for breathing, it can also be used as a propellant, a game changer for enabling economical space exploration for both a sustained lunar presence and lowering the cost of future Mars missions.

On a related note, Sierra Space is also participating in a groundbreaking research and development initiative for the Defense Advanced Research Projects Agency (DARPA), the 10-Year Lunar Architecture (LunA-10) capability study. The company is focused on integrating oxygen extraction, electrical storage, chemical recycling, and hydrogen-oxygen engine technology into a framework for a commercial lunar infrastructure.

About Sierra Space

Sierra Space is a leading commercial space company at the forefront of innovation and the commercialization of space in the Orbital Age®, building an end-to-end business and technology platform in space to benefit life on Earth. With more than 30 years and 500 missions of space flight heritage, the company is reinventing both space transportation with Dream Chaser®, the world’s only commercial spaceplane, and the future of space destinations with the company’s inflatable and expandable space station technology. Using commercial business models, the company is also delivering orbital services to commercial, DoD and national security organizations, expanding production capacity to meet the needs of constellation programs. In addition, Sierra Space builds a host of systems and subsystems across solar power, mechanics and motion control, environmental control, life support, propulsion and thermal control, offering myriad space-as-a-service solutions for the new space economy.