ROMEO, Mich.--(BUSINESS WIRE)--L&L Products announces the launch of its proprietary InsituCore™ foaming materials for lightweight composite manufacturing and its innovative PHASTER™ line of adhesives, sealants, reinforcements, and repair materials.

“After an extensive development process, we are proud to introduce these two new solutions to the market,” said Blake Synnestvedt, Director of Business Development at L&L Products North America. “For composites manufacturers, InsituCore™ will transform their existing process and comes with many benefits, from improved cycle times to waste reduction. Our unique PHASTER™ technology delivers outstanding adhesion and processibility to some of the most complex bonding, sealing, reinforcing and repairing applications.”

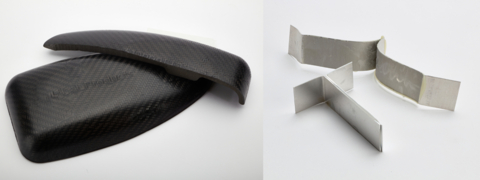

InsituCore™ Foaming Core Technology is a family of one-component, heat-activated foaming materials that generate internal pressure to create net shape, 3D parts that are both lightweight and strong in a simple, clean process. Compared to traditional manufacturing methods, this technology will enable faster cycle times, a reduction in waste material, and optimized production processes.

As part of the launch, L&L Products is introducing two types of one-component, heat-activated InsituCore™ materials: L-9008 is a thermosetting foam, and L-9080 is a thermoplastic foam. Potential applications include sporting goods, aircraft tray tables, insulated panels, automotive OEM and aftermarket parts. For more information on InsituCore™, visit InsituCore.llproducts.com.

PHASTER™ products feature proprietary two-component ambient curing technology with superior adhesion performance and processing ease, typically requiring no surface preparation. Compared to traditional polyurethane and epoxy systems, PHASTER™ is easy to process in various environmental conditions with low sensitivity to temperature and mix ratio differences.

The two PHASTER™ products making their debut are A-K700, a rapid-cure adhesive designed adhesion and superior peel strength to a variety of metal, ceramic, cementitious and polymeric substrates, and A-K607, a rigid foaming adhesive for use in structural gap filling applications and is machinable, paintable and sandable once cured. For more information on PHASTER™, visit phaster.llproducts.com.

Both InsituCore™ and PHASTER™ products will be on display at the L&L Products booth at CAMX, the Composites and Advanced Materials Expo.

About L&L Products

L&L Products combines expertise in materials science, advanced engineering, and manufacturing process optimization for customers to develop unique solutions that deliver structural reinforcement, substrate bonding, static sealing, and acoustic improvement for automotive, aerospace, commercial vehicle, construction, and consumer products applications. For nearly 70 years, our skilled chemists, scientists, and engineers have collaborated with customers around the world to make products lighter, stronger, and quieter. Today, L&L has over 1200 employees worldwide, 10 manufacturing facilities, and locations in 15 countries. For more information, visit www.llproducts.com.