SAN FRANCISCO--(BUSINESS WIRE)--MaintainX, the leading maintenance and frontline work execution platform, today released its first annual State of Industrial Maintenance Report, a comprehensive analysis of the challenges, trends and opportunities facing industrial maintenance teams. The global survey captures the sentiments of 1,165 maintenance, repair, and operations (MRO) professionals across a wide range of sectors, facility sizes, and locations.

The comprehensive report highlights the complex and ever-evolving landscape of industrial maintenance in 2024, and offers guidance on optimizing maintenance operations in the face of these complexities. It also highlights the continued battle against unplanned downtime and the increasing financial impact of even brief disruptions to production, delivery, or operations.

Chris Turlica, CEO and Co-Founder of MaintainX, said, "The decline in the frequency of unplanned downtime highlights that facilities across industries are making positive progress toward improving maintenance, asset reliability, and operational processes." He added, “This report highlights the importance of a proactive maintenance strategy in reducing excessive costs associated with unplanned downtime, improving productivity, and increasing overall efficiency."

Key 2024 Report Highlights Include:

- Downtime Cost Breakdown: The average cost of an hour of unplanned downtime hovers around $25,000, but for larger organizations, this figure can skyrocket to over $500,000.

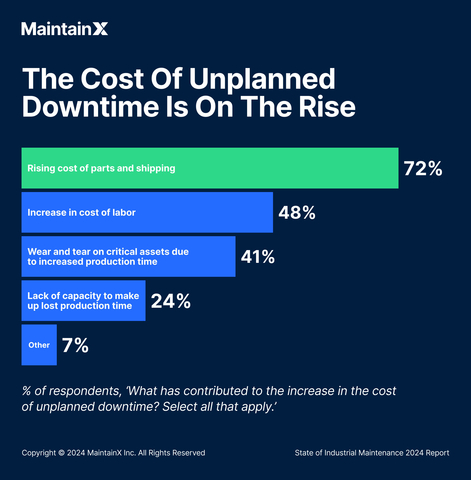

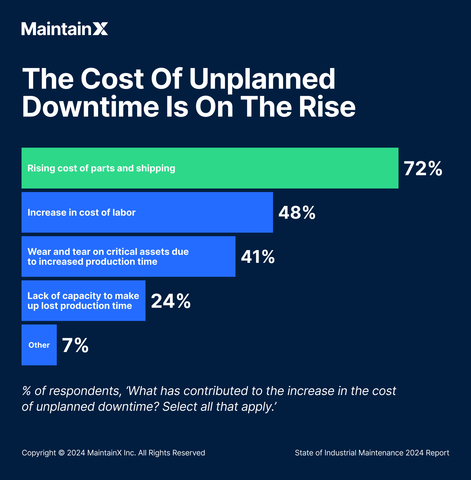

- Unplanned Downtime Down, Costs Up: 85% of facilities reported a stabilization or even a decrease in incidents of unplanned downtime over the past year, but nearly 30% reported higher downtime costs.

- Parts and Shipping Drive Cost Increases: 72% of facilities attributed the increase in cost of unplanned downtime to the rising cost of parts and shipping.

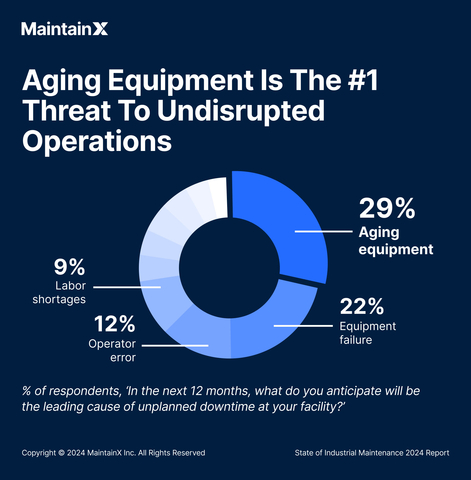

- Aging Equipment a Major Concern: 29% of MRO professionals believe that aging equipment will be the leading cause of unplanned downtime at their facility in the next 12 months.

In addition, the report sheds light on how maintenance programs face a growing skilled labor shortage. 60% of respondents identified it as the leading challenge to improving maintenance programs, particularly as older technicians retire or leave the workforce without a strong pipeline of younger talent to replace them. As the more experienced technicians leave, they take decades of critical knowledge along with them, hindering the progress of maintenance programs.

To navigate this challenging landscape, companies increasingly turn to technology to capture and persevere institutional knowledge, upskill their workforce, and streamline processes. Modern computerized maintenance management systems (CMMS) like MaintainX provide a centralized hub for critical information, making it accessible to seasoned team members and the next generation of technicians. These tools not only bridge knowledge gaps but also support data-driven decision-making and predictive maintenance strategies, including ensuring business continuity even as the workforce evolves.

The report further reveals a growing trend towards predictive maintenance as a strategic response to these challenges, emphasizing the importance of data-driven insights for optimizing maintenance operations and extending equipment lifespan.

"Maintenance data is the secret weapon,” said Christopher Wilcox, the Maintenance Manager at Univar Solutions, a leading global solutions provider for users of specialty ingredients and chemicals. He added, “It’s not just numbers on a spreadsheet; it’s the objective evidence you need to build a compelling case for resources and investments in your program. And when you present empirical, data-driven insights, you gain credibility and trust from decision-makers."

Access the full report here for a comprehensive look at the challenges and opportunities the industry faces today.

About MaintainX

Founded in 2018, MaintainX is the leading maintenance and frontline execution platform designed specifically for industrial and frontline teams. It helps companies streamline maintenance operations, improve asset management, and manage regulatory compliance and audits—all while delivering insights that can improve the bottom line. As a mobile-first platform trusted by over 8,000 customers worldwide, it delivers a modern, IoT-enabled solution for maintenance, reliability, and operations teams. MaintainX is reimagining industrial maintenance and operations to address the realities of today and the future ahead. For more information, visit www.maintainx.com.

MaintainX® is a registered trademark of MaintainX, Inc.