SAN JOSE, Calif.--(BUSINESS WIRE)--Daeduck Electronics announced the successful development of a large body FCBGA substrate for AI servers and data centers.

Established in 1965, Daeduck Electronics holds the distinction of being Korea's pioneering mass-producer of PCBs (Printed Circuit Boards), thus contributing significantly to the advancement of the nation's electronics sector for over six decades. With operations spanning five strategic locations, including four in Korea and one in Vietnam, coupled with its presence in key international markets through sales offices in the United States, China, and Taiwan, the company is poised for dynamic growth in tandem with the global package substrate market.

In recent years, Daeduck Electronics has strategically realigned its focus towards Semiconductor Package Substrates, marking a decisive entry into the FCBGA (Flip Chip Ball Grid Array) market through comprehensive investments commencing in 2021. This strategic movement has gained acclaim, positioning Daeduck Electronics as Korea's premier FCBGA manufacturer, underscored by tangible achievements and visible market impact.

FCBGA (Flip-chip Ball Grid Array) is a high-density semiconductor substrate that connects semiconductor chips and package substrates using the flip-chip method and improves electrical and thermal characteristics. Daeduck Electronics knocked the FCBGA market for AI servers and data centers, which was previously dominated by global peer companies in Japan and Taiwan.

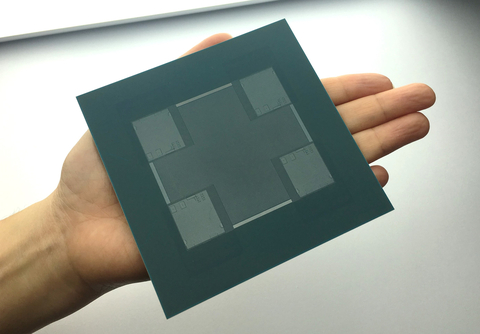

Daeduck Electronics' large body FCBGA substrate is a state-of-the-art substrate with a size of 100mm x 100mm, with 20 or more layers, and is applied to high-performance computing (HPC) chips, which are commonly known as data center chips. Daeduck Electronics' large body FCBGA substrate can also be applied to CPUs, GPUs, and 2.5D packages known as CoWoS (Chip on Wafer on Substrate) packaging used in AI (artificial intelligence) servers. In fact, it has acquired the technological capabilities to enter all product markets that can be entered through FCBGA.

In addition, the company is preparing for another challenge in the next-generation packaging market by developing a technology that integrates silicon capacitor embedding technology, bridge integration technology, and large body FCBGA substrate technology.

"As semiconductor technology advances rapidly, we will focus on expanding our market share in next-generation markets such as AI and autonomous driving through collaboration with global major companies based on our differentiated cutting-edge technology," said Young-Joo KO, CTO Daeduck Electronics.