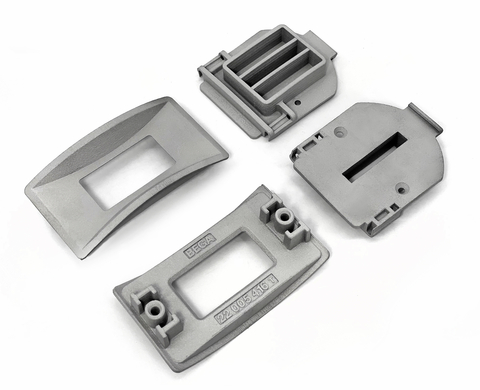

BOSTON--(BUSINESS WIRE)--Desktop Metal (NYSE: DM), a global leader in Additive Manufacturing 2.0 technologies for mass production, today announced that it will showcase binder jet 3D printed aluminum lighting components designed by BEGA, a German-based global leader in fine architectural outdoor and indoor lighting.

The parts were produced on the X25Pro mid-sized, production binder jet printing system with Al6061 powder.

“The Desktop Metal team continues to make incredible progress raising the bar in binder jet 3D printing with larger and more complex parts produced in Al6061 powder,” said Ric Fulop, Founder and CEO of Desktop Metal. “Our process for binder jetting parts that are capable of replacing complex, investment cast aluminum components continues to advance rapidly, with a number of production projects underway.”

After providing industry-first results for binder jetting aluminum on the InnoventX in 2021, Desktop Metal has continued to drive significant advancements for production-scale binder jetting in aluminum. In partnership with companies such as BEGA, Desktop Metal has now demonstrated a repeatable process for 99% dense aluminum with corrosion, thermal conductivity, fatigue, dimensional control, and T6 tensile properties — all of which meet or exceed the properties of common cast aluminum alloys used by our customers today.

The X25Pro used to produce the BEGA parts is a modified standard commercial system, specially outfitted with an inert or controlled atmosphere for use with reactive powders. The printer is located at Desktop Metal headquarters in Burlington, Mass., where it is being used for a variety of commercial partner projects. Customers interested in co-developing aluminum parts for production binder jet 3D printing applications are encouraged to reach out to Desktop Metal at TeamDM.com/X25Pro_Al6061.

Benefits of Binder Jet 3D Printing

Binder Jetting is widely regarded as the fastest method of metal 3D printing for high-volume output. This technology uses a digital file to quickly inkjet a binder into a bed of powder particles such as metal, sand, or ceramic to create a solid part, one thin layer at a time. When printing metals, the final bound metal part must be sintered in a furnace to fuse the particles together into a solid object. Ceramics, such as silicon carbide, can be sintered or infiltrated using a variety of methods.

Binder jet 3D printing, compared to both traditional manufacturing and other forms of 3D printing, enables manufacturers to more affordably produce complex parts with unique benefits, such as size and weight reductions, part consolidation, and performance improvements.

Because of the broad material flexibility of binder jet 3D printing, Desktop Metal employs a tiered qualification system for production of powdered materials, identifying materials as R&D Qualified, Customer-Qualified for specific applications, and DM Qualified for standard use. In all, more than 30 metals and ceramics are qualified on DM printers.

For more information about laser-free 3D printing with binder jetting, visit TeamDM.com/BJTguide.

About Desktop Metal

Desktop Metal (NYSE:DM) is driving Additive Manufacturing 2.0, a new era of on-demand, digital mass production of industrial, medical, and consumer products. Our innovative 3D printers, materials, and software deliver the speed, cost, and part quality required for this transformation. We’re the original inventors and world leaders of the 3D printing methods we believe will empower this shift, binder jetting and digital light processing. Today, our systems print metal, polymer, sand and other ceramics, as well as foam and recycled wood. Manufacturers use our technology worldwide to save time and money, reduce waste, increase flexibility, and produce designs that solve the world’s toughest problems and enable once-impossible innovations. Learn more about Desktop Metal and our #TeamDM brands at www.desktopmetal.com.

Forward-looking Statements

This press release contains forward-looking statements within the meaning of the federal securities laws. All statements other than statements of historical facts contained in these communications, including statements regarding Desktop Metal’s future results of operations and financial position, financial targets, business strategy, and plans and objectives for future operations, are forward-looking statements. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks and uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to: risks associated with the integration of the business and operations of acquired businesses; Desktop Metals’ ability to realize the benefits from cost saving measures; supply and logistics disruptions, including shortages and delays. For more information about risks and uncertainties that may impact Desktop Metal’s business, financial condition, results of operations and prospects generally, please refer to Desktop Metal’s reports filed with the SEC, including without limitation the “Risk Factors” and/or other information included in the Form 10-Q filed with the SEC on August 3, 2023, and such other reports as Desktop Metal has filed or may file with the SEC from time to time. These filings identify and address other important risks and uncertainties that could cause actual events and results to differ materially from those contained in the forward-looking statements. Forward-looking statements speak only as of the date they are made. Readers are cautioned not to put undue reliance on forward-looking statements, and Desktop Metal, Inc. assumes no obligation and does not intend to update or revise these forward-looking statements, whether as a result of new information, future events, or otherwise.