MINNEAPOLIS--(BUSINESS WIRE)--Niron Magnetics, the company pioneering the world’s first high-performance, rare earth-free permanent magnets, today announced it has raised $33 million in additional funding, with new investments from leading automotive manufacturers, GM Ventures and Stellantis Ventures, and previous local investors, Shakopee Mdewakanton Sioux Community (SMSC) and the University of Minnesota (UMN), amongst other investors. This new financing will allow Niron to expand its current pilot production facilities and scale manufacturing capacity for exclusive customer programs and initial sales of its Clean Earth Magnet®.

Permanent magnets are essential components in all automobiles, fundamental to audio systems, fuel pumps, air circulation, electric vehicle (EV) drivetrains, and much more. As more cars are bought around the globe and demand surges for EVs, so does the demand for more stable and sustainable alternatives to rare-earth materials. This new round of funding will advance the commercialization of Niron’s Iron Nitride-based Clean Earth Magnets, which are environmentally sustainable, globally manufacturable, and made from stable supply inputs. Further, Niron’s alternative to rare-earth magnets promises improved temperature stability compared to other options currently available on the market, which is critical for automotive use.

With the new investments from GM Ventures and Stellantis Ventures, and previous funding from Volvo Cars Tech Fund, Niron is now backed by three leading automotive manufacturers. This commitment demonstrates the potential of its Clean Earth Magnet technology to meet the automotive industry’s need to diversify and secure its supply chain with a viable alternative to rare earth magnets.

“Nearly 40 years ago, GM’s R&D team discovered and commercialized the world’s first high-powered, rare-earth permanent magnet material. GM Ventures’ investment in Niron’s Magnetics brings our rich history in specialized magnet innovation full circle,” said Anirvan Coomer, president of GM Ventures. “Niron’s Clean Earth Magnet could help GM make more affordable EVs for its customers out of more abundant materials.”

By increasing its pilot production capacities through team and facility expansions, Niron will be able to increase customer prototyping programs, and support small-scale product runs for key entry markets. In addition to automobiles, Niron’s Clean Earth Magnet technology can be used in consumer electronics and audio technology, industrial motors, pumps, compressors, wind turbines, and more.

“We were drawn to invest in Niron by the impressive sustainability benefits that its Clean Earth Magnet technology offers for vehicles and the inherent scalability of their solution,” said Adam Bazih, Managing Partner at Stellantis Ventures. “Making powerful magnets from plentiful commodity materials decouples new production from rare earth mine development and lowers overall environmental impact, which directly aligns with Stellantis’ commitment to reach carbon net zero by 2038.”

“We are thrilled that local organizations like SMSC and UMN continue to support Niron’s growth, and that GM and Stellantis both see the potential for Niron’s technology to help drive the automotive industry’s transition to EVs,” said Jonathan Rowntree, CEO at Niron. “We look forward to collaborating closely with all of our investors and partners to work towards enabling a rare earth-free future in magnetics.”

To learn more about Niron Magnetics and its Clean Earth Magnet technology, please visit https://nironmagnetics.com/.

About Niron Magnetics

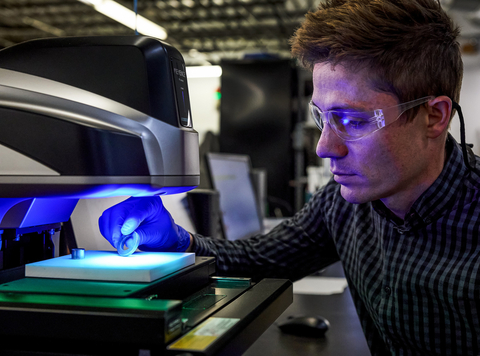

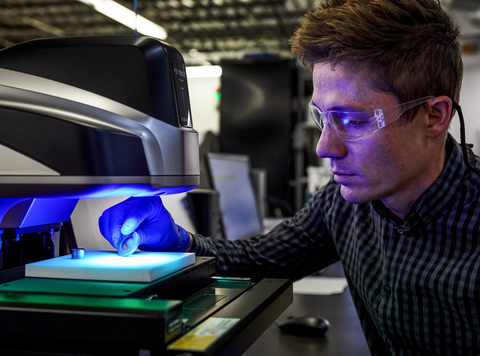

Niron Magnetics is scaling the world’s first advanced manufacturing process for the mass production of permanent magnets powered by its breakthrough material formulation. Niron’s proprietary Clean Earth Magnet® technology based on Iron Nitride enables magnets that possess inherently high magnetization, are free of rare earths and other critical materials, and will enable a revolution in the design of new electric motors and generators. For more information on Niron Magnetics and its technology, please visit https://www.nironmagnetics.com/.