BELOIT, Wis.--(BUSINESS WIRE)--NorthStar Medical Radioisotopes, LLC, a global innovator in the development, production and commercialization of radiopharmaceuticals used for therapeutic and medical imaging applications, today announced a corporate update highlighting progress across its key programs during the past twelve months, and indicating important upcoming milestones.

“NorthStar’s industry-leading reputation is grounded in technological innovation, successful execution and proven expertise, and we have made tremendous strides in advancing our portfolio over the past year,” said Stephen Merrick, Chief Executive Officer of NorthStar Medical Radioisotopes. “Our track record of success includes our program to supply U.S.-produced, non-uranium based Mo-99 for use in diagnostic imaging. NorthStar’s RadioGenix® Systems (technetium Tc 99m generator) have reliably delivered Tc-99m to meet the needs of radiopharmacies, health systems and patients, even during a twelve-month period fraught with serious supply shortages from overseas reactor-based producers.

Mr. Merrick continued, “Demand for therapeutic radiopharmaceuticals is increasing rapidly. NorthStar is poised to be the first commercial-scale producer of therapeutic radioisotopes Cu-67 and non-carrier added (n.c.a.) Ac-225 using advanced, environmentally preferable electron accelerator technology. NorthStar has further deepened and broadened our business platform with the recent establishment of a full-scale radiopharmaceutical CDMO/CMO services unit. This unit will enable us to develop and manufacture patient doses for pharmaceutical or biotechnology companies as well as share our radiopharmaceutical development and commercialization expertise with them where they may require additional infrastructure, resources or the specialized knowledge required for complex radiopharmaceutical development. These capabilities will help them develop and deliver products with the potential to improve care for even more patients with serious disease.

“In parallel with these initiatives, NorthStar’s imaging portfolio continues to advance,” Mr. Merrick further added. “The FibroScint program, a collaboration with Capella Imaging, to develop a Tc-99m agent to image fibrin, and collaboration with GE Healthcare to manufacture I-123 capsules are on track for further advancement this year. NorthStar has also made progress with adding value to the development of therapeutic radiopharmaceuticals through its agreements with Monopar Therapeutics and Inhibrx. These agreements have the potential to bring novel new treatments to patients with cancer, using radioisotopes to selectively destroy a wide range of cancer cells.

Mr. Merrick concluded, “This is a very exciting and dynamic time for NorthStar and all those involved in nuclear medicine. We are proud to be a leader in expanding the horizons of patient health by providing innovative solutions to ensure robust, reliable access to radioisotopes and radiopharmaceutical products that can make a positive difference in healthcare for people around the world.”

Commercial U.S. Mo-99/Tc-99m production and reliable supply

Currently, and for more than four years, NorthStar, with the University of Missouri Research Reactor (MURR®), remains the only program that is a commercialized U.S. producer of Mo-99. The Company is aggressively expanding and establishing environmentally preferable dual production and processing hubs for additional Mo-99 capacity to better meet customer demand and ensure sustainable U.S. supply. Two facility expansion projects nearing completion in Beloit, Wisconsin, will augment current Mo-99 production and processing in Columbia, Missouri, conducted in partnership with MURR®.

-

NorthStar’s Beloit, Wisconsin, Accelerator Production facility expansion will ensure additional Mo‑99 capacity, enable flexible production scheduling, including Sunday production, and minimize customer supply risks. NorthStar estimates that electron accelerator technology will increase its Mo-99 program production capability to meet nearly 40% of U.S. demand. The Accelerator Production facility is expected to come online, upon completion of regulatory submissions, in late 2023/early 2024.

- In January 2023, NorthStar set a new industry precedent in advancing non-uranium based commercial production of Mo-99 by achieving a “two beams on target” milestone in producing Mo-99 with electron accelerators, thus validating the proof of concept for large-scale U.S. Mo-99 production without the use of uranium.

- In November 2022, the United States Department of Energy’s National Nuclear Security Administration (DOE/NNSA) recognized NorthStar for completion of construction and equipment installation for its new Accelerator Production facility for Mo-99. NorthStar is the first and only program to achieve commercialized Mo-99 production through collaboration with the DOE/NNSA. The DOE/NNSA provided financial and technical support for the project as part of its program to increase U.S. production of the vital medical radioisotope Mo-99 without the use of highly enriched uranium, which is a proliferation-sensitive material.

- In September 2022, NorthStar and IBA signed a new agreement for two additional Rhodotron® TT300 HE electron beam accelerators, and associated beamlines, from IBA for the production of Mo-99. This agreement marks a total of five Rhodotron® accelerators that NorthStar has contracted with IBA to date.

- NorthStar’s Isotope Processing facility in Beloit will complement current Columbia processing capacity for Mo-99 source vessels. The facility will enable NorthStar to more than double its current Mo-99 processing capabilities. NorthStar expects to bring the Isotope Processing facility online, upon completion of regulatory submissions, in late 2023/early 2024.

- NorthStar’s unique production technology for Mo-99 offers a highly differentiated environmental advantage over traditional uranium-based methods. It results in comparatively benign, short-lived and easily managed waste streams, in contrast to uranium-based methods that result in highly radioactive, long-lived waste with significant burdens to global waste streams.

RadioGenix® System commercial progress

NorthStar’s innovative, high tech radioisotope separation platform, the RadioGenix System, uses U.S.-produced, non-uranium based Mo-99 to produce Tc-99m, the most widely used medical radioisotope that informs patient management decisions in 40,000 U.S. imaging studies daily. Ongoing product enhancements continue to maximize operational utility and efficiency of RadioGenix Systems in producing Tc-99m, including a well-advanced development program for the next generation radioisotope separation platform for the production of Tc-99m.

- RadioGenix Systems have generated almost two million doses of Tc-99m for patients’ diagnostic imaging studies to date, with utilization continuing to steadily increase.

- They have provided reliable Tc-99m supply to radiopharmacies and health system customers despite intermittent, and sometimes extended, shortages from suppliers using legacy, uranium-based production methods.

Commercial-scale therapeutic radioisotope production – Cu-67 and n.c.a. Ac-225

NorthStar is poised to be the first commercial-scale supplier of the important therapeutic radioisotopes Cu-67 and n.c.a. Ac-225, both used to deliver therapeutic doses of radiation to destroy cancer cells in patients with serious disease, while sparing healthy tissue. Development of Cu-67 has been historically hampered by a lack of commercial chelators to securely hold copper in place without leakage in vivo, which limited demand for the isotope. Development of Ac-225 based therapies has been severely constrained by limitations in current production technology and very limited supply.

- NorthStar is applying its commercial-scale radioisotope production experience with Mo-99 to provide reliable Cu-67 and n.c.a. Ac-225 supply to advance clinical research and ensure adequate availability for commercial radiopharmaceutical products. The Company is leveraging its technology expertise demonstrated by the successful launch of the RadioGenix System and non-uranium based Mo-99, and key learnings from sophisticated techniques required in constructing its advanced Accelerator Production and Isotope Processing facilities.

- Like all NorthStar processes, electron accelerator production of Cu-67 and n.c.a. Ac-225 radioisotopes is non-uranium based and highly efficient.

Cu-67 program

NorthStar has an exclusive agreement with Clarity Pharmaceuticals for supply of Cu-67 to support Clarity’s clinical stage Targeted Copper Theranostic (TCT) programs with three theranostic trials currently underway in the United States. The TCT platform using Clarity’s proprietary SAR chelators to securely hold copper has recently expanded with their SAR-Bombesin prostate cancer program, while their SAR-bisPSMA and SARTATE theranostic programs are reaching later stage clinical development, thus driving demand for Cu‑67.

- NorthStar anticipates availability of radiochemical grade Cu-67 within a few weeks.

- Northstar’s electron accelerator production of Cu-67 is high volume and highly sustainable, allowing for an alternative to reactor-based therapeutic isotopes such as lutetium-177. The process is highly efficient with no associated long-lived radioactive contaminants.

- Cu-67 presents a unique opportunity to manufacture high-volume therapeutic radioisotopes domestically in the United States.

n.c.a. Ac-225 program

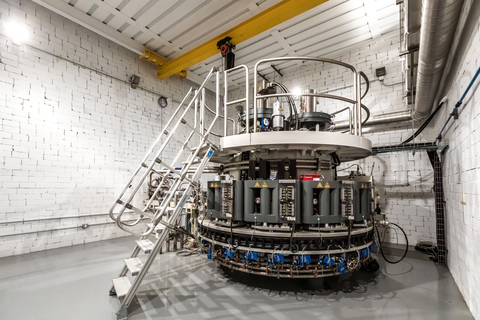

- In March 2023, NorthStar achieved a major milestone in commercial-scale production of n.c.a. Ac-225 with the delivery and installation of a custom-built IBA Rhodotron® TT300-HE (High Energy) electron beam accelerator at its new Ac-225 Production facility in Beloit, Wisconsin. The state-of-the-art facility will be dedicated exclusively to the production of n.c.a. Ac-225 and is part of NorthStar’s expansion plan to ensure scalable, reliable and environmentally preferable production of n.c.a. Ac-225, that, once attached to a molecule, will be used for treatment of patients with cancer and other serious diseases. Progress on the facility is well underway, with initial production of radiochemical grade Ac-225 planned for late 2023/early 2024. NorthStar expects to submit a Drug Master File to the FDA in 2024, which, upon acceptance, will allow it to provide cGMP grade Ac-225.

- In October 2022, NorthStar and Eckert & Ziegler announced an agreement for the purchase of specially designed hot cells and related equipment for NorthStar’s Ac-225 Production facility and commercial-scale production of n.c.a. Ac-225. Hot cells are specially designed shielded enclosures that allow the safe handling of radioactive material.

-

NorthStar has multiple supply agreements in place to provide clinical trial supply and commercial-scale quantities of Ac-225, and expects additional supply agreements during 2023. NorthStar has n.c.a. Ac-225 production capacity to meet all customer needs, from research through commercialization, and can readily scale up further as market demand increases.

- In October 2022, NorthStar and Radiopharm Theranostics signed a supply agreement under which NorthStar will provide Radiopharm with its n.c.a. Ac-225 for drug trials involving targeted alpha therapy in multiple disease areas.

- In August 2022, NorthStar and Aktis Oncology signed a supply agreement under which NorthStar will provide Aktis with its n.c.a. Ac-225 to advance development of its proprietary tumor-targeting agents intended to deliver transformative efficacy for patients with solid tumors.

- In July 2022, NorthStar and Clovis Oncology signed a supply agreement under which NorthStar will provide Clovis with its n.c.a. Ac-225 to radiolabel its lead peptide-targeted radionuclide therapeutic candidate, FAP-2286, which targets fibroblast activation protein (FAP), a promising theranostic target with expression across many tumor types.

- In June 2022, NorthStar and Curie Therapeutics (now Mariana Oncology) signed a priority access supply agreement under which NorthStar will provide Curie with its n.c.a. Ac-225 to advance its multimodal pipeline of precision radiopharmaceuticals to address broad unmet needs in treatment of patients with solid tumors.

- Additional n.c.a. Ac-225 supply agreements have been signed, but not disclosed, under confidentiality agreements with NorthStar pharmaceutical collaborators.

- NorthStar is utilizing environmentally preferred production technology for its high purity n.c.a. Ac-225. Electron accelerators will produce n.c.a. Ac-225 that is free of long-lived radioactive contaminants and byproducts associated with many other production methods, which pose regulatory and waste management challenges for hospitals and health systems.

NorthStar is evaluating additional potential opportunities for the production and commercialization of other novel radioisotopes to support the needs of researchers and pharmaceutical drug developers.

Therapeutic radiopharmaceutical development

NorthStar is actively engaged with select collaborators in advancing therapeutic radiopharmaceutical development and commercialization programs for the treatment of cancer and other serious disease.

- In February 2023, NorthStar and Monopar Therapeutics expanded their radiopharmaceutical collaboration for MNPR-101, a first-in-class anti-uPAR humanized monoclonal antibody planned to be radiolabeled with Ac-225 for treatment of advanced solid tumors and severe COVID-19. Based on promising recently generated preclinical imaging results, the companies committed to additional funding for future development of MNPR-101.

- In January 2023, NorthStar and Inhibrx announced a collaboration to develop and produce novel radiopharmaceuticals for the treatment of cancer. Under the agreement, NorthStar will support the development of a pre-specified number of Inhibrx’s novel biologic products by providing Ac-225 supply, specialized radiopharmaceutical development capabilities and access to its integrated radiopharmaceutical CDMO services. Under the agreement, NorthStar will prepare Inhibrx patient doses for clinical studies and, upon approval, may manufacture and supply radionuclides for Inhibrx’s commercial use.

Radiopharmaceutical Contract Development and Manufacturing Organization (CDMO/CMO) services

NorthStar announced a significant expansion of its business platform in November 2022 with the formation of a new, patient-focused radiopharmaceutical development and CDMO/CMO services unit. It will provide collaborator companies with a full range of customized radiopharmaceutical development and commercialization services, and serve NorthStar in progressing its own radiopharmaceutical programs as well as developing and manufacturing radiopharmaceutical patient doses. Ground has been broken on a new 47,000 square foot facility on the Company’s Beloit, Wisconsin campus. When complete, NorthStar will be the first and only U.S. company housing commercial-scale, multi-radioisotope production and radiopharmaceutical development services on the same campus, enabling collaborator companies to realize logistical, regulatory and cost benefits. NorthStar expects to deliver CDMO/CMO services in early 2025, pending appropriate licensure and regulatory approvals.

NorthStar’s CDMO/CMO services unit will provide patient dose development and manufacturing capability and specialized radiopharmaceutical expertise to pharmaceutical and biotechnology companies, to help them develop and deliver products with the potential to improve care for patients with cancer and other serious disease.

Diagnostic imaging portfolio

NorthStar is actively developing and growing its strategic portfolio of positron emission tomography (PET) and single photon emission computed tomography (SPECT) radiopharmaceuticals for diagnostic imaging.

- NorthStar continues to advance FibroScint, a novel fibrin-specific diagnostic imaging agent labeled with Tc-99m for SPECT imaging. Pending successful development, FibroScint will have an initial application in the imaging of thrombus (blood clots) associated with left ventricular assist devices (LVADs), and other potential imaging applications in deep vein thrombosis and pulmonary embolism. The Company plans to use RadioGenix System-produced Tc-99m in clinical studies of FibroScint. An Investigational New Drug (IND) filing for a Phase 1 study is planned for 2024.

- NorthStar is collaborating with GE Healthcare to produce and distribute iodine-123 (I-123) capsules for use in SPECT imaging. I-123 is the proven radiopharmaceutical standard in diagnostic imaging studies for thyroid disease. GE Healthcare’s Pharmaceutical Diagnostics unit will manufacture and supply NorthStar with I-123 capsules under the NorthStar label using a new, state-of-the-art production system. Upon regulatory approvals, NorthStar will retain exclusive U.S. marketing and distribution rights for I-123 capsules in 100 µCi and 200 µCi formulations. FDA approval is expected in 2023.

Corporate development and industry leadership

NorthStar is firmly positioned for sustained, long-term growth and increasing global industry prominence.

Company growth

With more than 350 highly-skilled employees, NorthStar is a responsible corporate citizen and engaged community member. Its Beloit, Wisconsin campus is planned for long-term expansion to meet patients’ healthcare needs and growing global demand. NorthStar recently purchased an additional 22 acres of land to accommodate its new radiopharmaceutical CDMO facility and future growth. The 55-acre campus includes NorthStar’s corporate headquarters, an Accelerator Production facility for Mo-99 and Cu-67, an Isotope Processing facility, an Ac-225 Production facility for exclusive production of the therapeutic radioisotope Ac-225, and the radiopharmaceutical CDMO/CMO facility. NorthStar also has two R&D facilities in Madison, Wisconsin, and office space and a processing facility, located in the MURR® complex, in Columbia, Missouri.

Environmentally responsible radioisotope production

NorthStar continues to set leadership standards for domestic, environmentally preferable radioisotope production across its portfolio, to meet the needs of health systems and patients. NorthStar is committed to ensuring that health systems have access to innovative, clean solutions that minimize the environmental footprint of their nuclear medicine departments. All NorthStar processes are non-uranium based and employ the Company’s “Reduce, Recover, Reuse” approach for reliable, domestic and environmentally sound medical radioisotope production.

New executives

- In June 2022, Frank Scholz, Ph.D., was promoted to President and Chief Operating Officer of NorthStar. Dr. Scholz has extensive operational experience in the pharmaceutical and life sciences industries, and will help lead the next phase of NorthStar’s growth. He holds oversight of Corporate Development, External Affairs, Sales, Marketing and Public Relations in addition to his previous responsibilities for Program Management, Regulatory Affairs, Engineering & Technology, Manufacturing Operations & Supply Chain, and Advanced Radioisotope & Therapeutic Technologies. Dr. Scholz will be instrumental in driving NorthStar’s initiatives across its portfolio.

- In May 2022, NorthStar appointed Monica Andersen as Vice President, Human Resources. She will hold responsibility for the Company’s Human Resources and Organizational Health functions. Ms. Andersen’s depth of human resources leadership in organizational design, talent recruitment, cultural enrichment, planning and development will further accelerate NorthStar’s growth.

About the RadioGenix® System (Technetium Tc 99m Generator)

The RadioGenix System is an innovative, high tech separation platform that is approved for processing non-uranium based molybdenum-99 (Mo-99) for the production of the important medical radioisotope, technetium-99m (Tc-99m). Prior to availability of RadioGenix technology, the U.S. supply chain for Mo-99 has been subject to frequent and sometimes severe interruptions that negatively impacted patient health care. Approved by the U.S. Food and Drug Administration (FDA) in 2018, the RadioGenix System is the first and only on-site, automated isotope separation system of its kind for use with non-uranium based Mo-99, designed to help alleviate shortage situations and expand domestic supply.

Indication and Important Risk Information about the RadioGenix® System and Sodium Pertechnetate Tc 99m Injection USP

INDICATION

The RadioGenix® System is a technetium Tc-99m generator used to produce Sodium Pertechnetate Tc 99m Injection, USP. Sodium Pertechnetate Tc 99m Injection is a radioactive diagnostic agent and can be used in the preparation of FDA-approved diagnostic radiopharmaceuticals.

Sodium Pertechnetate Tc 99m Injection is also indicated in:

- Adults for Salivary Gland Imaging and Nasolacrimal Drainage System Imaging (dacryoscintigraphy).

- Adults and pediatric patients for Thyroid Imaging and Vesicoureteral Imaging (direct isotopic cystography) for detection of vesicoureteral reflux.

IMPORTANT RISK INFORMATION

- Allergic reactions (skin rash, hives, or itching) including anaphylaxis have been reported following the administration of Sodium Pertechnetate Tc 99m Injection. Monitor all patients for hypersensitivity reactions.

- Sodium Pertechnetate Tc 99m Injection contributes to a patient’s long-term cumulative radiation exposure. Ensure safe handling to protect patients and health care workers from unintentional radiation exposure. Use the lowest dose of Sodium Pertechnetate Tc 99m Injection necessary for imaging and ensure safe handling and preparation to protect the patient and health care worker from unintentional radiation exposure. Encourage patients to drink fluids and void as frequently as possible after intravenous or intravesicular administration. Advise patients to blow their nose and wash their eyes with water after ophthalmic administration.

- Radiation risks associated with the use of Sodium Pertechnetate Tc 99m Injection are greater in children than in adults and, in general, the younger the child, the greater the risk owing to greater absorbed radiation doses and longer life expectancy. These greater risks should be taken firmly into account in all benefit-risk assessments involving children. Long-term cumulative radiation exposure may be associated with an increased risk of cancer.

- Temporarily discontinue breastfeeding. A lactating woman should pump and discard breastmilk for 12 to 24 hours after Sodium Pertechnetate Tc 99m Injection administration.

- Sodium Pertechnetate Tc 99m Injection should be given to pregnant women only if the expected benefits to be gained clearly outweigh the potential hazards.

- Only use potassium molybdate Mo-99, processing reagents, saline and other supplies, including kit/packs, provided by NorthStar Medical Radioisotopes. Do not administer Sodium Pertechnetate Tc 99m Injection after the 0.15 microCi of Mo-99/mCi of Tc-99m limit has been reached or when the 24 hour expiration time from elution is reached, whichever occurs earlier. Follow step-by-step instructions for use provided in the Operator’s Guide, RadioGenix System 1.2.

To report SUSPECTED ADVERSE REACTIONS, contact NorthStar® Medical Radioisotopes, LLC at 1-844-438-6659; or FDA at 1-800-332-1088 or www.fda.gov/medwatch.

For RadioGenix® System version 1.2 Full Prescribing Information, click here or visit https://www.northstarnm.com/wp-content/uploads/2023/02/RadioGenix-System-version-1.2-Package-Insert-Rev-08-Jan-2023.pdf.

About NorthStar Medical Radioisotopes, LLC

NorthStar Medical Radioisotopes is a commercial-stage nuclear medicine company focused on advancing patient care by providing diagnostic and therapeutic radioisotopes, novel radiopharmaceuticals and customized radiopharmaceutical development services. Its proven management team and state-of-the-art, environmentally preferable and non-uranium based technologies have made it an emerging leader at the forefront of U.S. medical radioisotope and radiopharmaceutical production. NorthStar’s molybdenum-99 (Mo-99) program is the sole source of domestic Mo-99, used to generate the standard-of-care diagnostic imaging radioisotope for assessing heart disease and cancer. It is expanding its industry-leading position in the growing area of therapeutic radioisotopes, used in targeted radiopharmaceutical therapy to treat cancer and other serious diseases, and is poised to be the first commercial-scale producer of non-carrier added (n.c.a.) actinium-225 (Ac-225) and copper-67 (Cu-67). NorthStar’s Radiopharmaceutical Contract Development and Manufacturing Organization (CDMO/CMO) services unit will provide customized service offerings and specialized radiopharmaceutical expertise to help biopharmaceutical companies rapidly advance their development and commercialization programs. For more information about NorthStar’s comprehensive portfolio and patient-focused services, visit: www.northstarnm.com.