ANN ARBOR, Mich.--(BUSINESS WIRE)--The tedious task of loading and unloading parts into machines has long been a bread-and-butter application for cobots gaining significant traction in the industry. With its 1,750 mm (68.9 in) reach and 20kg payload (44.1 lbs.), the new UR20 from Universal Robots greatly expands automation opportunities such as the ability to reach further into machines, tend several machines in the same cycle, and handle 25% heavier parts. Despite being UR’s heaviest robot, the UR20 is the lightest cobot in its class, weighing only 64kg (141.1 lbs.) making it both a versatile technical tool and a manual laborer.

“More than half of all U.S. manufacturing tasks are automatable, a fact that businesses start to realize as they simply cannot fill open positions,” says Universal Robots’ senior manager of applications development and strategic marketing, Joe Campbell. “We are launching a redefined cobot that has been completely re-engineered from the ground up, focused on freeing up more manpower within a wide range of human-scale automation tasks.”

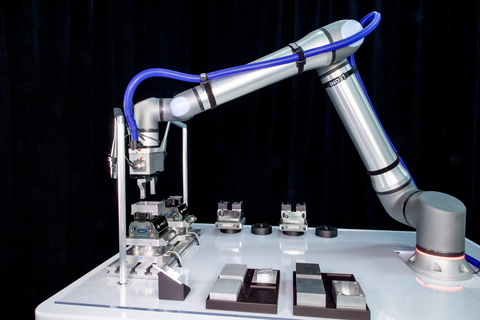

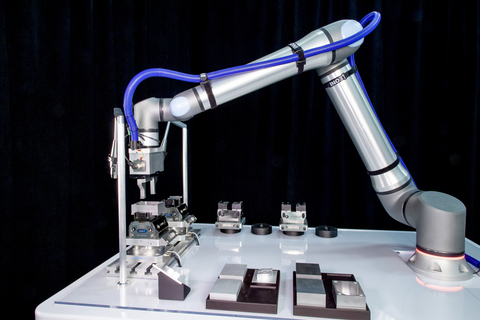

At Universal Robots’ IMTS booth 236949, attendees will experience first-hand what that looks like as the UR20 loads and unloads heavy workpieces into a machine fixture requiring a long reach. “We have completely re-engineered the cobot’s field-serviceable joints, that deliver 30% more speed and torque within a closed capsule,” says Universal Robots’ VP of innovation and strategy, Anders Beck, explaining how the UR20’s base joint produces 700 Newton-meters of torque. “This is more than a performance model Tesla produces on all of its wheels. Even with the increase in reach and torque, we’ve managed to retain the cobot’s 50 microns repeatability, while still using standard single-phase power.”

Universal Robots also kept the intuitive user interface, pioneered by the company, while incorporating advanced software enhancements, giving users unprecedented motion control capabilities. The rapidly expanding UR+ ecosystem of third-party components and application kits, certified to be plug-and-play with UR cobots, also supports the UR20. At IMTS, UR+ partner SCHUNK, will launch the EGU universal parallel electric gripper with the ability to handle varying part dimensions. The new gripper integrates seamlessly with the new UR20through a URCap (software handshake between the peripheral and the robot arm).

Growing number of UR cobot-powered OEM solutions showcased

Universal Robots recently posted a robust 30% growth across the first two quarters of 2022 compared to the first half of 2021. A significant contributor to UR’s growth is OEMs that now increasingly incorporate UR cobots into full solutions, a sales channel that grew 39% year-over-year. At IMTS, UR has invited several OEM and UR+ partners to its booth, including Vectis Automation, Hirebotics, VersaBuilt Robotics, Robotiq, Kane Robotics, PCC Robotics, and Mid Atlantic Machinery.

New applications for fabricating, machine tending and finishing tasks

For fabricators, Vectis Automation will demo the water-cooled version of its Cobot Welding Tool, delivering heavy duty welds along with the Vectis Cobot Plasma Cutting Tool that enables complex cuts on high-mix 3D parts and tubes for a fraction of the cost of existing 3D shape cutting automation. Hirebotics will showcase its Cobot Welder with a rotary positioner to demonstrate how the system can communicate with positioners to weld parts that aren't possible with just the cobot. The Press Brake Operator Package from Mid Atlantic Machinery showcases a UR10e on a modular parts cart with a machine tool interface and a zone safety scanner that ensures shop safety.

New innovative ways for cobots to interact with CNCs will be highlighted by Robotiq’s new Machine Tending Solution that emulates the machine operator with no need to modify or alter the machine controls. Since it is non-intrusive, the new Robotiq solution will work with any brand of CNC. VersaBuilt’s UR+ certified Mill Automation System with a MultiGrip automation work-holding will allow machinists to easily add any new CNC parts that can be held with a vise. PCC Robotics will demonstrate an efficient machine cell setup as a UR10e equipped with OnRobot’s dual 3FG15 gripper mounted on EasyRobotics’ ProFeeder feeds parts to an air vise.

For a finishing touch, Kane Robotics will show the GRIT™ XL-X robotic system that is ideal for sanding, grinding and finishing, including customized programming and robust data solutions.

Free cobot training sessions at the show

Attendees looking to use cobots for automation tasks but unsure where to begin or how to program, are invited to attend free hands-on training sessions inside McCormick Place at IMTS, each session tailored a specific application taught by certified UR product trainers. “Our cobots will be in more than 20 other booths at the show as well, each showcasing different ways to incorporate cobots into machining applications,” says UR’s Joe Campbell. “We’re looking forward to meet every IMTS attendee no matter where they’re at in their automation journey.”

Press Kit: Download it here.

About Universal Robots

Universal Robots aims to empower change in the way work is done using its leading-edge robotics platform. Since introducing the world’s first commercially viable collaborative robot (cobot) in 2008, UR has developed a product portfolio including the UR3e, UR5e, UR10e, UR16e, and UR20 reflecting a range of reaches and payloads. Each model is supported by a wide selection of end-effectors, software, accessories and application kits in the UR+ ecosystem. This allows the cobots to be used across a wide range of industries and means that they can be redeployed across diverse tasks. The company, which is part of Teradyne Inc., is headquartered in Odense, Denmark, and has offices in the USA, Germany, France, Spain, Italy, the Czech Republic, Romania, Turkey, China, India, Japan, South Korea, Singapore and Mexico. Universal Robots has installed over 50,000 cobots worldwide. For more information, please visit www.universal-robots.com or read our blog at blog.universal-robots.com.