TAICHUNG, Taiwan--(BUSINESS WIRE)--The world's first plastic and rubber trade exhibition will open in Germany in October. GMA, which has not participated in the exhibition for 2 years due to COVID-19, will return to the international exhibition again. This is also the seventh time GMA has participated in K fair. It will bring three innovations and highlights.

First, Excellent processing. GMA extrusion die processing is finished in-house, for meeting more customized requirement. This time, GMA will exhibit the beautiful extrusion die surface of HASTELLOY ALLOY (C276) that is processed.

Second, various design of extrusion die. New modified polymer and recycle polymer are used for production, GMA shows extrusion die that is special design for producing high transparency products, this die is with optimized channel and external deckle system for adjusting width.

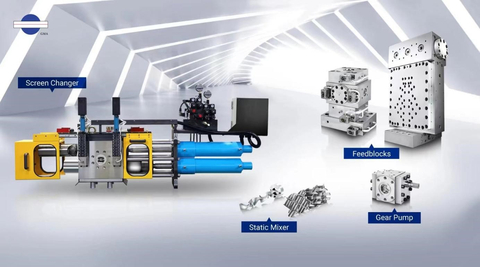

Third, completely extrusion line solution. GMA focus on extrusion die design and manufacture. GMA knows extrusion die and auxiliary parts very well. GMA provide customer beneficial solution.

GMA Machinery, which started from CNC (Computer Numerical Control) processing, has been in business for 33 years since 1989.

Nowadays, GMA Machinery can deliver services and extrusion die that customers can rely on. Applications range from food and beverage packaging, fabric, furniture leather, transportation and recreational products to the particular needs of the highly demanding optoelectronic and medical industries.

In all industries, GMA Machinery is one of the leaders in auto-die for multi-layer transparent film. GMA Machinery has deployed ahead of time, developing extrusion dies for processing recycled plastic to maintain its competitive edge and to do its part for environmental conservation.

One-Stop Quality Assurance Toward Global Consulting and Maintenance Services

Since extrusion dies is one of key factors to extrusion production lines , GMA Machinery targets overseas markets with fast-growing economies and industries.

GMA Machinery is capable of CNC processing, chrome plating, assembly and quality inspection, from design to completion, almost all completed in the factory, with nearly 95% self-made molds and complete testing equipment to ensure quality.

GMA Machinery is also designated by customers to be a maintenance center for customers’ professional consultation and various brands of extrusion die.

For more information on GMA Machinery Enterprise Co. Ltd., visit: