KARIYA, KUWANA, Japan & HSINCHU, Taiwan--(BUSINESS WIRE)--DENSO Corporation, a leading mobility supplier, and United Semiconductor Japan Co., Ltd. (“USJC”), a subsidiary of global semiconductor foundry United Microelectronics Corporation (NYSE: UMC; TWSE: 2303)(“UMC”), today announced that the companies have agreed to collaborate on the production of power semiconductors at USJC’s 300mm fab in order to serve the growing demand in the automotive market.

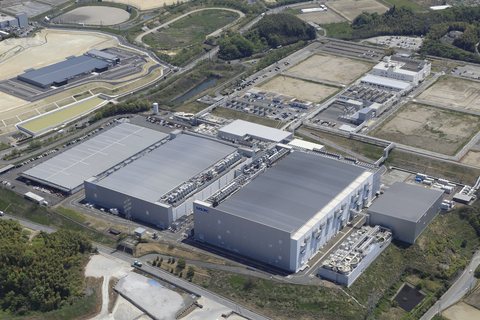

An insulated gate bipolar transistor (IGBT) line will be installed at USJC’s wafer fab, which will be the first in Japan to produce IGBTs on 300mm wafers. DENSO will contribute its system-oriented IGBT device and process technologies while USJC will provide its 300mm wafer manufacturing capabilities to bring the 300mm IGBT process into mass production, scheduled to start in the first half of 2023. This collaboration is supported by the renovation and decarbonization program for indispensable semiconductors of Japan’s Ministry of Economy, Trade and Industry.

As the development and adoption of electric cars accelerate amid a global effort to reduce carbon emissions, the demand for semiconductors required in the electrification of vehicles is also rapidly increasing. IGBTs are core devices in power cards, serving as efficient power switches in inverters to convert DC and AC currents in order to drive and control electric vehicle motors.

“DENSO is very glad to be the member of first companies in Japan to start mass production of IGBTs on 300 mm wafers,” said Koji Arima, President of DENSO. “Semiconductors are becoming increasingly important in the automotive industry as mobility technologies evolve, including automated driving and electrification. Through this collaboration, we contribute to the stable supply of power semiconductors and electrification of automobiles.”

“As a key foundry player in Japan, USJC is committed to supporting the government’s strategy to boost domestic semiconductor production and the transition to more environmentally friendly electric vehicles,” said Michiari Kawano, President of USJC. “We are confident that our foundry services certified by automotive customers combined with DENSO’s expertise will produce high quality products to power the automotive trends of tomorrow.”

“We are pleased to have this win-win collaboration with a leading company such as DENSO. This is an important project for UMC and will expand our relevance and influence in the automotive segment,” said Jason Wang, Co-President of UMC. “With our robust portfolio of advanced specialty technologies and IATF 16949 certified fabs in diversified locations, UMC is well placed to serve demand across auto applications, including advanced driver assistance systems, infotainment, connectivity, and powertrain. We look forward to capitalizing on more cooperation opportunities going forward with top players in the automotive space.”

About DENSO

DENSO is a $44.6 billion global mobility supplier that develops advanced technology and components for nearly every vehicle make and model on the road today. With manufacturing at its core, DENSO invests in its 200 facilities to produce thermal, powertrain, mobility, electrification, & electronic systems, to create jobs that directly change how the world moves. The company’s 168,000+ employees are paving the way to a mobility future that improves lives, eliminates traffic accidents, and preserves the environment. Globally headquartered in Kariya, Japan, DENSO spent 10.0 percent of its global consolidated sales on research and development in the fiscal year ending March 31, 2021. For more information about global DENSO, visit https://www.denso.com/global

About UMC

UMC (NYSE: UMC, TWSE: 2303) is a leading global semiconductor foundry company. The company provides high quality IC fabrication services, focusing on logic and various specialty technologies to serve all major sectors of the electronics industry. UMC’s comprehensive IC processing technologies and manufacturing solutions include Logic/Mixed-Signal, embedded High-Voltage, embedded Non-Volatile-Memory, RFSOI and BCD etc. Most of UMC's 12-in & 8-in fabs with its core R&D are located in Taiwan, with additional ones throughout Asia. UMC has total 12 fabs in production with combined capacity over 800,000 wafers per month (8-in equivalent), and all of them are certified with IATF 16949 automotive quality standard. UMC is headquartered in Hsinchu, Taiwan, plus local offices in United States, Europe, China, Japan, Korea & Singapore, with worldwide total 20,000 employees. For more information, please visit: https://www.umc.com.

Note from UMC Concerning Forward-Looking Statements

Some of the statements in the foregoing announcement are forward-looking within the meaning of the U.S. Federal Securities laws, including statements about introduction of new services and technologies, future outsourcing, competition, wafer capacity, business relationships and market conditions. Investors are cautioned that actual events and results could differ materially from these statements as a result of a variety of factors, including conditions in the overall semiconductor market and economy; acceptance and demand for products from UMC; and technological and development risks. Further information regarding these and other risks is included in UMC’s filings with the U.S. Securities and Exchange Commission. UMC does not undertake any obligation to update any forward-looking statement as a result of new information, future events or otherwise, except as required under applicable law.