Fulcrum and Paperless Parts Partner to Help Manufacturers Win More Business

Fulcrum and Paperless Parts Partner to Help Manufacturers Win More Business

New integration with Paperless Parts supercharges the capabilities of Fulcrum and empowers manufacturers with newfound efficiency and speed in the estimating and quoting process.

MINNEAPOLIS & BOSTON--(BUSINESS WIRE)--Two of the nation’s most innovative manufacturing software companies, Fulcrum and Paperless Parts, have partnered to streamline the workflow of manufacturers like never before. The two companies have worked together to ensure the integration of their two systems is seamless, giving shared customers the ability to do everything from quoting a job to shipping the final product more efficiently and effectively.

Older generations of ERP systems — designed to help large companies connect their production to their accounting system — tried to do a bit of everything and did not allow for much flexibility. The modern manufacturing tech stack is built to adapt to the needs of individual manufacturers and take advantage of what each software piece does best. For Paperless Parts, this means offering a more automated solution for returning quotes quickly and consistently in order to win more business; for Fulcrum, it means building a system that is both intuitive and powerful, allowing manufacturers to take on more jobs without overworking current staff or machines. With the integration of these modern technologies, both Paperless Parts and Fulcrum provide manufacturers with the flexibility to customize the quoting process to their specific business needs.

“Fulcrum and Paperless Parts are tools my business uses daily. The integration and the proactive support of both teams allow us to be nimble, solve problems fast, and deliver a quality product and experience to our customers,” said Steven Mayfield, Managing Partner at National Tube Processing. “While we have only been ‘live’ on the integration since March, we are excited about what the future holds for National Tube Processing with this software tech stack driving us forward.”

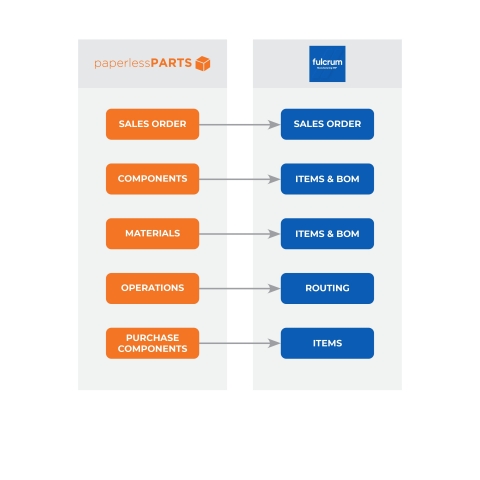

Paperless Parts’ centralized estimating and quoting tool empowers manufacturers to make better decisions with their data by reducing errors with a more streamlined and automated estimating process. This data then flows into Fulcrum, giving manufacturers clear visibility into their production needs and schedule, allowing them to increase throughput and decrease wasted time and resources. Fulcrum applies machine learning and advanced heuristics to give manufacturers key information in real time, allowing them to make the right decisions to help move their business forward by connecting every element of the production process, from sales to shipping.

“The future of manufacturing is seamless connectivity,” said Fulcrum founder and CEO Yu Sunny Han. “That means both within a single business and in the manufacturing ecosystem broadly. No one wants to spend their time reentering data that already exists elsewhere, and this integration with Paperless Parts will mean our mutual customers don’t have to.”

“It is exciting to work with other well-funded companies who share our mission of supporting the future of manufacturing,” said Jason Ray, co-founder and CEO of Paperless Parts. “We’re excited to integrate with Fulcrum to give manufacturers the full benefits of a modern connected software stack.”

Customers of both companies will have access to this integration immediately. For more information, visit fulcrumpro.com/integrations and paperlessparts.com/demo-fulcrum/.

About Fulcrum

Fulcrum is a cloud-based SaaS solution that helps manufacturers modernize and become more efficient, allowing them to compete more effectively within the global marketplace. By connecting all aspects of their workflow and providing real-time insights into what is going on in their business, Fulcrum enables manufacturers to make the right decision at the right time to fuel their growth. By focusing specifically on the needs of small- and medium-sized manufacturers, Fulcrum helps the entire supply chain work together, driving efficiency and sustainability through high-quality, low-waste production. Learn more at fulcrumpro.com

About Paperless Parts

Paperless Parts is on a mission to help job shops, contract manufacturers and finishing companies improve business and grow by providing them with the most advanced, secure, cloud-based sales and quoting system available. The software streamlines manufacturers’ existing workflows by combining modern business process automation tools with a configurable geometric pricing engine that drives speed and consistency in the quoting process. The platform integrates with CRM and ERP systems to supercharge front office operations and sales teams, and enables more efficient responses to RFQs for a variety of manufacturing processes. Manufacturers across the U.S. have analyzed over 1 million job files using the platform and are winning over $1 billion worth of orders a year.

Contacts

Danielle Goodman

danielle.goodman@paperlessparts.com