ALBUQUERQUE, N.M.--(BUSINESS WIRE)--Researchers at Carnegie Mellon University (CMU) have developed a low-cost sensor that can identify COVID-19 antibodies in approximately 10 seconds. The novel sensor is based on a special structure of tiny gold electrodes that are 3D printed using the Optomec Aerosol Jet process. The technology would allow clinicians to instantly and accurately detect the COVID-19 antibodies due to the specific geometry and surface characteristics of the printed structure. The low-cost sensor, which is just entering trials with COVID patients, could prove to be a key tool in understanding the path and concentration of the pandemic and could be a critical enabler in opening up certain parts of the economy.

The breakthrough test identifies two antibodies of the virus and is capable of detection even at very low concentrations through an electrochemical reaction sensed in the 3D printed structure within a simple handheld device that interfaces with a smartphone. CMU researchers have also begun research that will allow this platform to detect the active virus, in addition to its antibodies.

The 3D printed sensor was developed by the team of Rahul Panat, Associate Professor of Mechanical Engineering at Carnegie Mellon University who researches additive manufacturing techniques for producing biosensing devices and human-computer interfaces. “My research team was working on 3D printed high-performance sensors to detect dopamine, a chemical in the brain, when we realized that we could adapt our work for COVID-19 testing. We shifted our research to apply our expertise to combatting this devastating pandemic,” said Panat. “The Aerosol Jet process was critical to producing a sensor with high sensitivity and speed.”

Professor Panat collaborated with Shou-Jiang Gao, leader of the Cancer Virology Program at UPMC Hillman Cancer Center and professor of microbiology and molecular genetics at the University of Pittsburgh. More information is available on the CMU website here: https://engineering.cmu.edu/news-events/news/2020/09/14-covid-rapid-test.html

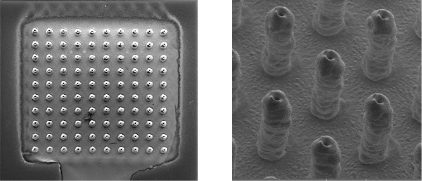

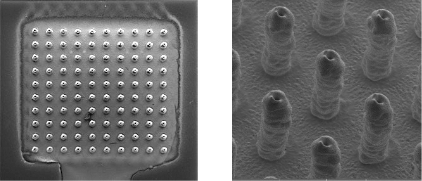

Aerosol Jet is a production process, developed by Optomec, capable of printing extremely precise conductive and non-conductive materials with features as fine as 10 microns. It is used in advanced semiconductor packaging, 3D antenna and sensor production, medical device manufacturing, aerospace and other industries. For the CMU COVID-19 sensor, ink droplets containing nanoparticles were precisely placed to build a matrix of 100 gold pillars in 2 mm square at high speed. The pillars were then coated with reduced graphene oxide, which binds the antibodies to the gold electrodes. The device has a potential to detect other viruses such as Zika, Ebola and HIV, according to the researchers.

Optomec is a privately held, rapidly growing supplier of Additive Manufacturing systems. Optomec’s patented Aerosol Jet Systems for printed electronics and LENS 3D Printers for metal components are used by industry to reduce product cost and improve performance. Together, these unique printing solutions work with the broadest spectrum of functional materials, ranging from electronic inks to structural metals and even biological matter. Optomec has more than 300 marquee customers around the world, targeting production applications in the electronics, energy, life sciences and aerospace industries. For more information, visit optomec.com.

LENS is a registered trademark of Sandia National Labs; Aerosol Jet is a registered trademark of Optomec, Inc.