LONDON--(BUSINESS WIRE)--Predictive maintenance is undoubtedly one of the most talked-about topics in maintenance and asset management. To gauge where manufacturing companies currently stand with regard to their predictive maintenance ability and where they plan to be in the future, we surveyed 150+ companies in Germany, the US, and the UK. The survey helped us gain unprecedented insights into the current capabilities of businesses and their plans to improve predictive maintenance. It also revealed that only a small percentage possessed the capabilities and already employed the necessary tools, people, and processes to drive growth in the new industrial revolution.

To gain a competitive edge, organizations must act on data-driven insights. Book a FREE Demo to learn how we can help you leverage and act on these insights!

As per the garnered information, one of the main factors preventing operators from investing entirely in predictive maintenance is the ability to gather and analyze data. However, with data growing in complexity and volume with every passing day, businesses are finding it challenging to predict future scenarios using traditional predictive maintenance approaches. Quantzig, in its recent article, sheds light on the role of predictive maintenance analytics, its importance, and offers vital insights from the survey.

Request a FREE proposal to learn more about our predictive maintenance analytics solutions for manufacturing companies.

“Predictive maintenance analytics leverages process data and advanced analytical methods to predict machine failures well in advance,” says an analytics expert at Quantzig.

Why Quantzig?

120 + |

1500 |

550+ |

15 + |

Global clients including Fortune 500 companies |

Comprehensive projects |

Data scientists and analytics experts |

Years of experience

|

Detailed information about Quantzig’s predictive analytics capabilities can be accessed at https://bit.ly/34ns7lL

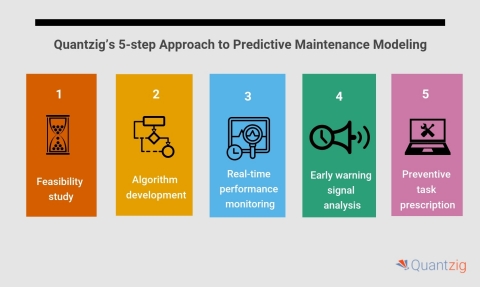

Quantzig’s 5-step Approach to Predictive Maintenance Modeling

Step 1: A feasibility study

Step 2: Algorithm development

Step 3: Real-time performance monitoring

Step 4: Early warning signal analysis

Step 5: Preventive task prescription

At Quantzig, we understand the challenges faced by our clients in the manufacturing sector, and predictive maintenance tops the list. Our predictive maintenance analytics solutions are designed by experts who possess comprehensive industry and market knowledge to deliver improved insights and efficiencies. By harnessing our extensive expertise in predictive maintenance analytics, we help forward-looking companies lead in the new industrial revolution. By leveraging our predictive maintenance solutions, organizations can eliminate potential defects, establish a maintenance schedule, and achieve tangible business benefits.

At Quantzig, we have a cross-functional team that comprises of researchers, analytics experts, and data scientists who assist our clients in implementing solutions that help devise a digital strategy that can move the needle. Speak to our analytics experts right away!

Follow us on LinkedIn and Twitter to keep abreast of the emerging trends in predictive modeling.

About Quantzig

Quantzig is a global analytics and advisory firm with offices in the US, UK, Canada, China, and India. For more than 15 years, we have assisted our clients across the globe with end-to-end data modeling capabilities to leverage analytics for prudent decision making. Today, our firm consists of 120+ clients, including 55 Fortune 500 companies. For more information on our engagement policies and pricing plans, visit: https://www.quantzig.com/request-for-proposal