AEye Reveals Advanced MEMS That Delivers Solid-State Performance and Reliability Needed to Advance Adoption of Low-Cost LiDAR

AEye Reveals Advanced MEMS That Delivers Solid-State Performance and Reliability Needed to Advance Adoption of Low-Cost LiDAR

Independent tests validate that the new 4Sight™ long range intelligent MEMS-based sensor exceeds automotive and industrial standards for shock and vibe

DUBLIN, Calif.--(BUSINESS WIRE)--AEye, Inc., an artificial perception pioneer today announced that their 4Sight™ M sensor based on patented intelligent perception system design has established a new standard for sensor reliability. In testing completed at NTS, one of the most respected testing, inspection, and certification companies in the US, the 4Sight M scan block surpassed automotive qualification for both shock and vibe. AEye also announced the availability of 4Sight – a new family of advanced 1550nm LiDAR vision systems.

“The LiDAR industry has struggled with attaining solid-state performance, especially when trying to achieve sufficiently high resolution at long range,” said Luis Dussan, Co-Founder and CEO of AEye. “With the very public failures of several Optical Phased Arrays and Flash LiDAR concepts, MEMS-based systems were seen as a potential solution, but the inability of FMCW or other TOF systems to effectively reduce the size of or harden their MEMS continues to be a stumbling block. Our non-arrayed micro-MEMS is at the core of our unique system design and helps us solve this challenge-providing the automotive industry the combination of reliability, performance and price they have been seeking.”

4Sight is the fifth-generation sensor from AEye and is based on AEye’s powerful iDAR™ platform. AEye’s unique patented system design is elegant in its simplicity with one laser, one MEMS, one receiver, and one SOC. Driven by extensible software, 4Sight is designed from the ground up to identify and deliver salient information while exceeding all industry quality and reliability standards, and can be manufactured at scale at low cost. To prove its reliability, AEye recently engaged NTS, to conduct extensive shock and vibration testing, on the 4Sight sensor. The results of the test showed a 4Sight Sensor can sustain a mechanical shock of over 50G, random vibration of over 12Grms (5-2000Hz), and sustained vibration of over 3G.

“Having funded hundreds of radar and LiDAR projects over the years,” said Allan Steinhardt, AEye’s Chief Scientist and former Chief Scientist at DARPA. “I appreciate the power of simple and elegant design and how that impacts system reliability. In real terms, our 4Sight remains fully operational significantly past the acceleration point where air bags deploy, and passengers black out.”

AEye is changing the calculus for adding long range, high-performance LiDAR to a vehicle. Now automotive OEMs and Tier 1s along with trucking, construction, transit, rail, ITS, aerospace, and defense markets can implement LiDAR with the confidence that it can withstand forces similar to those generated by the recent historic launch of a Falcon rocket.

Size Matters – Not all MEMS are created equal

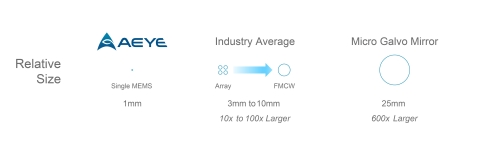

The size of the mirror in a MEMS largely determines its reliability. Larger mirrors also have larger inertia, generating 10x to 600x more torque from shock and vibration events. In addition, larger mirrors do not allow for fast, quasi-static movement for agile scanning, which is key to intelligent and reliable artificial perception. Learn more here.

The unique patented system design of AEye’s MEMS allows a mirror that is less than 1mm in size. Other LiDAR systems use 3mm to 25mm mirrors – which equates to 10X – 600X larger surface area. (See Figure 1) In addition, lacking intelligence-driven agility, these systems are forced to rely on these larger mirrors increasing both complexity and cost. Combined with an 1550nm amplifiable laser and sophisticated receiver, the small mirrors in AEye’s custom-designed MEMS are produced in volume using standard processes and deliver the unique high-performance of iDAR with ground breaking reliability.

“The philosophy of AEye unique iDAR approach is to use resources where they have the greatest leverage for the application and make it the highest resolution, longest range, and most reliable LIDAR engine on the market,” said Jan Grahmann, Head of Microoptical Devices and Systems at the Fraunhofer Institute for Photonic Microsystems. “Unlike competitors that have to work with large MEMS mirrors for long distances, we have worked with AEye to prove that a solid-state MEMS-scanning based LIDAR engine with MEMS mirrors at their design space sweet spot provide exceptional performance and extreme shock and vibration resistance.”

“The cumulative fatigue data from these tests is used to determine the lifespan, quality and reliability of 4Sight,” said Indu Vijayan, 4Sight Product Manager. “Passing these tests demonstrate that 4Sight will endure the vibrations of a vehicle for its rated lifetime as well as shock of 50G impact events such as collisions or massive potholes. From an automotive perspective, it also shows that 4Sight sensors are on-track to pass shock and vibration standards such as GMW3172 and LV124.”

Built on unique patented technologies

AEye’s iDAR platform and 4Sight sensors are backed by over 27 granted patents, 10 more patents in process, and over 1,300 claims covering system and component design and implementation. This broad patent portfolio includes several groundbreaking innovations such as the only scanning lidar patent granted for a camera and lidar sharing the same optical axis (co-boresited), eliminating enormous parallax correction; MEMS agile control, feedback, and intraframe sampling, allowing for edge processing and low-latency feedback; and advanced perception, enabling real-time capabilities such accurate intraframe calculation of object velocity.

Given the current constraints in travel, AEye is also announcing another industry-first innovation in the launch of Raptor - a unique high-performance web-based remote demo platform. Raptor will enable participants to engage in a real-time interactive test drive with an AEye engineer. From the comfort of their own home or office, AEye’s customers and partners will have the ability to see what a truly software-defined sensor can do and witness the record breaking 4Sight M performance in real time and to customize the demo to meet their specific use cases. Please contact 4sight@aeye.ai to schedule a demo.

About AEye

AEye is an artificial perception pioneer and creator of iDAR™, a perception system that acts as the eyes and visual cortex of autonomous vehicles. Since its demonstration of its solid-state LiDAR scanner in 2013, AEye has pioneered breakthroughs in intelligent sensing. The company is based in the San Francisco Bay Area, and backed by world-renowned investors including Kleiner Perkins Caufield & Byers, Taiwania Capital, Hella Ventures, LG Electronics, Subaru-SBI, Aisin, Intel Capital, Airbus Ventures, and others. For more information, please visit www.aeye.ai

About Fraunhofer IPMS

The Fraunhofer Institute for Photonic Microsystems is part of the Fraunhofer Group for Microelectronics, and is engaged in various regional and international networks in the filed microsystems and photonics. Located in Dresden, The Fraunhofer IPMS is located is your access to know-how, expertise and modern R&D infrastructure in the field of optical sensors and actuators, integrated circuits, microsystems (MEMS/MOEMS) and nanoelectronics.

Contacts

AEye, Inc.

Jennifer Deitsch

jennifer@aeye.ai

925-596-3945