Shin-Etsu Develops New Technology for Reducing the Amount of Platinum Used in Silicone Release Coatings by About One-half

Shin-Etsu Develops New Technology for Reducing the Amount of Platinum Used in Silicone Release Coatings by About One-half

TOKYO--(BUSINESS WIRE)--Shin-Etsu Chemical Co., Ltd. (Head office: Tokyo; President: Yasuhiko Saitoh) has developed a “Reduced-Platinum Reaction Curing System Technology,” and we are proceeding with productization by integrating this technology into silicone release coatings.

Silicone release coatings generally use a platinum-based curing catalyst. However, platinum is an expensive precious metal, and due to such issues as the depleting of its limited resources, a reduction in the amount of usage in the curing process has been sought.

By implementing a silicone composition that exhibits high reactivity, Shin-Etsu’s newly developed “Reduced-Platinum Reaction Curing System Technology” enables the carrying out of curing that results in the lowering of the amount of platinum usage by about 1/2 compared to that of conventional usage.

Using this new technology, we expect to contribute to resource saving, and at the same time, we will be able to meet the varied requests of our customers. Shipments of samples have already begun, and this new product has been obtaining good evaluations from customers.

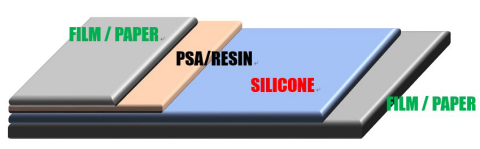

Silicone release coatings add peelability (releasability) to adhesive agents by coating such backing materials as paper and film. The main applications are primarily as coated release paper for stickers, labels, and adhesive tapes as well as for release films and manufacturing process release liner, and they are used in a wide range of applications.

Taking advantage of Shin-Etsu Chemical’s superior product quality and technological strengths as well as our system for detailed response to our customers’ requests, going forward Shin-Etsu will continue to strive to meet the needs of the diversifying market.

Contacts

Shin-Etsu Chemical Co., Ltd.

Public Relations Dept.

Tetsuya Koishikawa

Tel: 03-3246-5091, or from outside Japan: 81-3-3246-5091

Fax: 03-3246-5096, or from outside Japan: 81-3-3246-5096

e-mail: sec-pr@shinetsu.jp

www.shinetsu.co.jp