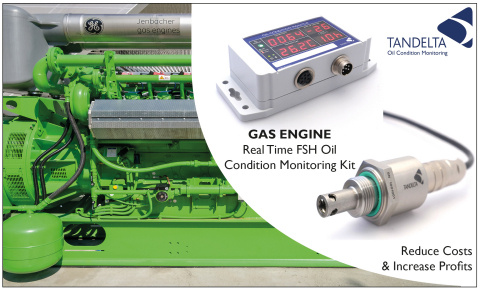

SHEFFIELD, England--(BUSINESS WIRE)--The new Gas Engine oil condition monitoring kit from Tan Delta Systems can be quickly and easily fitted to any gas engine and enables the oil to be monitored and tracked continuously in real time enabling significantly reduced maintenance costs, increased equipment efficiency and extended equipment life. Operators can expect their investment returned in under four months followed by many years of net financial and operational benefits.

The kit includes everything needed for quick and easy installation on any gas engine operating in any environment. No more need for expensive laboratory oil testing. Reduce daily operating costs by optimising maintenance schedules. Protect against long term incremental equipment damage that reduces equipment efficiency and life, through the early detection and remedy of issues. Rest assured that your gas engine is being constantly and reliably monitored in real time with our unique full spectrum holistic real time oil condition monitoring technology.

Our new Gas Engine Monitoring Kit is based around the Tan Delta OQSx oil condition monitoring sensor that uses Tan Delta’s patented technologies to deliver full spectrum holistic (FSH) oil condition monitoring. FSH monitoring is where any change in oil quality, no matter the cause – wear or contamination – is detected, measured and reported. Unlike other oil quality/condition sensors that may focus on one condition element, FSH monitors everything and ensures that nothing is missed and any issues are detected before damage is caused to equipment.

About Tan Delta Systems:

Tan Delta Systems is the global leader in oil condition monitoring technologies and systems that reduce equipment operating costs. Our unique FSH technology ensures that any oil quality change is detected and reported in real time. Our real time oil condition monitoring products are used by leading equipment operators around the world to reduce their costs and increase their profits. Distributor inquiries welcome.