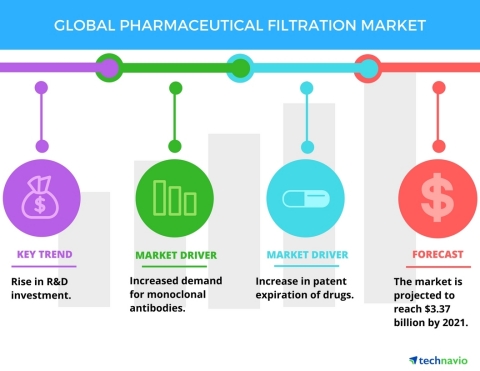

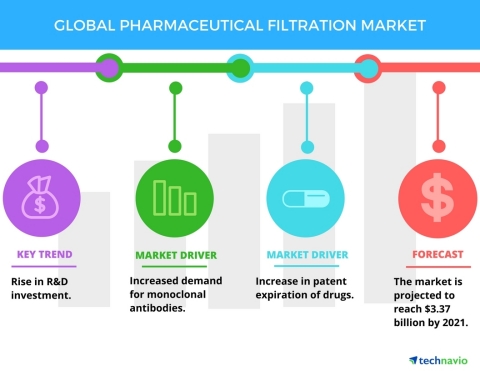

LONDON--(BUSINESS WIRE)--Technavio’s latest market research report on the global pharmaceutical filtration market provides an analysis of the most important trends expected to impact the market outlook from 2017-2021. Technavio defines an emerging trend as a factor that has the potential to significantly impact the market and contribute to its growth or decline.

The global pharmaceutical filtration market is expected to grow at a CAGR of more than 11 % during the forecast period. The increasing prevalence of heart attacks and diabetes has increased the demand for pharmaceutical products such as antibodies, hormones, and vaccines, which further increase the adoption of pharmaceutical filtration, thereby increasing their demand.

This report is available at a USD 1,000 discount for a limited time only: View market snapshot before purchasing

Buy 1 Technavio report and get the second for 50% off. Buy 2 Technavio reports and get the third for free.

The top three emerging market trends driving the global pharmaceutical filtration market according to Technavio research analysts are:

- Adoption of laboratory automation

- Advances in nanofiber technology

- Clean and safe research and manufacturing environment

Looking for more information on this market? Request a free sample report

Technavio’s sample reports are free of charge and contain multiple sections of the report including the market size and forecast, drivers, challenges, trends, and more.

Adoption of laboratory automation

Due to the reduction in lab fees, profitability per test is decreasing, which makes it essential for the laboratories to focus on volume rather than value. There is also a heavy pressure on quality and error-free results. This compels the labs to lean toward more automated systems with effective workflow solutions.

According to Amber Chourasia, a lead analyst at Technavio for lab equipment research, “Several studies have shown that pharmaceutical filtration technologies enhance operations at laboratory and research centers by providing optimum purification of drugs. Labs are also approaching institutes to get valid certification of automation. In the coming years, healthcare centers and laboratories are likely to benefit from standardization and automation, as fully automated molecular platforms are emerging into the market as game changers.”

For instance, Eaton’s Automatic Self Cleaning Filters allow continuous flow, simplified maintenance, and worry-free operation. Self-cleaning filters reduce product loss, improve flow consistency, and require minimal operators impute. Therefore, the usage of filters and filter media in the pharmaceutical industry helps to reduce process time and provide better-quality products, which augurs well for the growth of the market during the forecast period.

Advances in nanofiber technology

Nanotechnology has provided several novel products with superior properties for a wide range of applications and nanofiber is one of the major successes of nanotechnology. Furthermore, pharmaceutical industries need highly purified water, air, gases, and chemicals, which should be free from contaminants, allergens, pollutants, and hazardous biological agents. Hence, nanofibers are being used to improve air filtration efficiency of filters and media in pharmaceutical industries.

Nanofiber webs act as protective fabrics against infectious and environmental agents in the pharmaceutical industry in addition to providing affinity membranes for filtering heavy metals, which was difficult by conventional purification methods. These factors are expected to propel market growth during the forecast period.

Clean and safe research and manufacturing environment

Strong quality assurance and quality control systems certify raw materials and consumables to meet external and internal standards in the pharmaceutical industry. Therefore, several precautions need to be taken to prevent contamination of final products, which creates the need for pharmaceutical filtration.

According to the FDA, cleanroom should be designed, maintained, and controlled to prevent particle and microbiological contamination of drug products. Cleanrooms for API manufacturing are used for drug products with high sensitivity to microbes and airborne particulates.

“Cleanroom quality is maintained through air filtration, room architecture, and control of personnel. Hence, the need for clean and safe research and manufacturing environment mandates pharmaceutical filtration process, which will boost market growth during the forecast period,” says Amber.

Browse Related Reports:

- Global Toxicology Testing Market 2017-2021

- Global Clinical Laboratory Services Market 2017-2021

- Global White Biotechnology Market 2017-2021

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio’s report library consists of more than 10,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio’s comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

If you are interested in more information, please contact our media team at media@technavio.com.