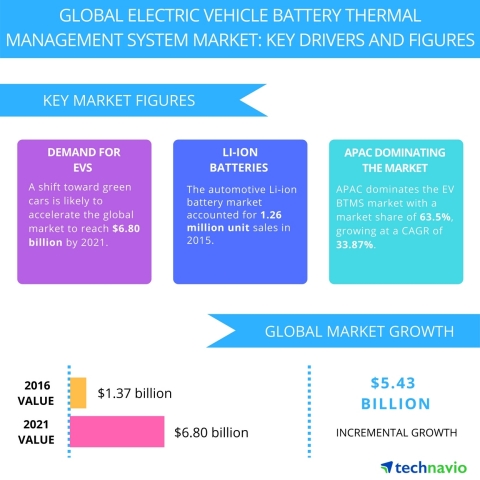

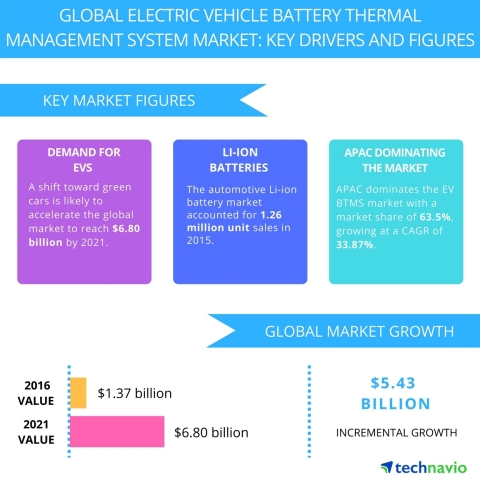

LONDON--(BUSINESS WIRE)--Technavio’s latest market research report on the global electric vehicle battery thermal management system (EV BTMS) market provides an analysis of the most important trends expected to impact the market outlook from 2017-2021. Technavio defines an emerging trend as a factor that has the potential to significantly impact the market and contribute to its growth or decline.

According to Neelam Barua, an industry expert for automotive electronics research at Technavio, “The advances in EV have drastically increased the workload on batteries, thereby increasing the demand for a BTMS solution that enables a wider operating temperature range, enhances the lifespan of the battery, and proliferates the range of EVs. These factors will drive the global EV BTMS market during the forecast period, which is expected to grow remarkably at close to 38% CAGR.

Request a sample report: http://www.technavio.com/request-a-sample?report=55542

Technavio’s sample reports are free of charge and contain multiple sections of the report including the market size and forecast, drivers, challenges, trends, and more.

The top three emerging trends driving the global EV BTMS market according to Technavio automotive research analysts are:

- Advances in thermal management technology

- Ease of diagnosis through CAN bus interface

- High-density, high-power, small-sized Li-ion batteries

Advances in thermal management technology: PCM and GIHP

The introduction of high-density batteries and fast chargers in the EV market has increased the heat generation in battery packs. Although DX BTMS is adopted as a solution to these issues, R&D programs to introduce new TMS technologies for batteries are under progress. The upcoming trend in BTMS is phase change materials (PCM) and gas injection heat pump (GIHP) system. A PCM is used mainly to limit overheating, while the GIHP is used to increase the battery temperature to permissible levels in cold weather conditions.

As the battery becomes overheated, PCM absorbs the heat quickly and uses that energy to change the internal structure of the material. Graphite matrix is mainly used as PCM. This can be used as a substitute to passive air cooling technology for small battery packs.

“However, GIHP, where a gas injector is used to push the refrigerant to the compressor, which is shared with the AC in the EV, is a current trend in the market. This system can achieve 26% improved efficiency in city driving conditions, and it consumes 30% less energy to heat to reduce the temperature from -20°C to 0°C,” says Neelam.

Ease of diagnosis through CAN bus interface

Controller Area Network (CAN) bus is a message-based protocol used for diagnosis and troubleshooting of the most critical systems in the vehicle based on their configuration and can operate up to 1 Mbit/s. The increased integration of high-speed CAN in automotive systems has reduced the complexity of a hard-wired architecture.

CAN has found its use in EVs over the last five years due to the multifaceted electronic structure of batteries and battery control/management system and associated power electronics. The growing adoption of CAN bus has eased the installation of BMS in an EV by integrating a CAN bus interface in this unit. This has enabled the BMS to connect with other on-board units and engine control units (ECUs) in the vehicle and process information. For instance, if the battery overheats, BMS can send a message to trigger the BTMS ensuring optimal battery operation.

High-density, high-power, small-sized Li-ion batteries

Battery cost accounts for nearly 70% of the EV rate, and 30% of the overall battery cost comes from the BTMS cost. So, a major cost reduction in battery and BTMS needed to be achieved to introduce cheaper EV models in the market. This decrease can be achieved by designing Li-ion battery designs that have high power density.

Therefore, battery manufacturers have developed battery packs that are designed for high-power, high-density with optimized cell chemistries and they will be introduced in the market from early 2017. Higher power density will allow hybrid batteries to be much smaller, therefore much cheaper in future. Instead of a 1.0 kWh battery, these Li-ion batteries will be only about 0.3 to 0.5 kWh. With lesser power rating, inexpensive refrigeration techniques such as DX can control the heat dissipation of batteries.

Browse Related Reports:

- Global Battery Monitoring Solutions Market 2016-2020

- Global Advanced Energy Storage Systems Market 2016-2020

- Global Automotive Power Tailgate System Market 2017-2021

Become a Technavio Insights member and access all three of these reports for a fraction of their original cost. As a Technavio Insights member, you will have immediate access to new reports as they’re published in addition to all 6,000+ existing reports covering segments like automotive services; powertrain; and wheels and tires. This subscription nets you thousands in savings, while staying connected to Technavio’s constant transforming research library, helping you make informed business decisions more efficiently.

About Technavio

Technavio is a leading global technology research and advisory company. The company develops over 2000 pieces of research every year, covering more than 500 technologies across 80 countries. Technavio has about 300 analysts globally who specialize in customized consulting and business research assignments across the latest leading edge technologies.

Technavio analysts employ primary as well as secondary research techniques to ascertain the size and vendor landscape in a range of markets. Analysts obtain information using a combination of bottom-up and top-down approaches, besides using in-house market modeling tools and proprietary databases. They corroborate this data with the data obtained from various market participants and stakeholders across the value chain, including vendors, service providers, distributors, re-sellers, and end-users.

If you are interested in more information, please contact our media team at media@technavio.com.