KUALA LUMPUR, Malaysia--(BUSINESS WIRE)--Unisem recently shipped their one billionth packaged MEMS device and they continue to invest capex in both MEMS assembly equipment and the development of additional factory floor space for this expanding market. With MEMS device revenues forecasted to grow from 11.9 Billion USD in 2015 to 20 Billion USD by 2021 (Yole), Unisem sees MEMS as a strategic part of their technology and growth plans moving forward. With over 9 years of experience developing MEMS packaging solutions, Unisem estimates that their MEMS unit volumes will grow by over 50 percent over the next 12 months.

Part of Unisem’s growth strategy for MEMS packaging includes the dedication of additional factory floor space. In their state of the art factory in Chengdu, China, they have recently completed the installation and certification of a 1200 sq. meter class 100 clean room to support the assembly needs of MEMS microphones, combination cavity packages, and other devices that either require or benefit from this level of controlled environment.

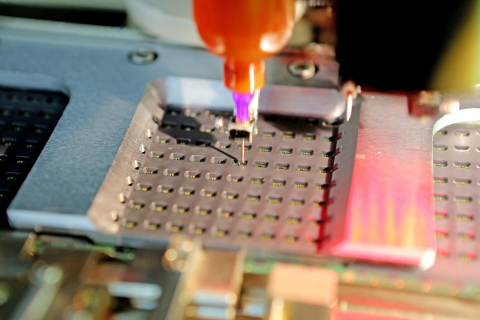

In addition to the new class 100 clean room, Unisem also has brought in Film Assisted Molding capability to support the expansion of their MEMS molded cavity package offerings. Film Assisted Molding allows Unisem to target both the automotive and industrial MEMS pressure sensor market as well as the growing market for consumer pressure, humidity, temperature, gas sensors and combinations of these. This technology enables Unisem to use leadframe based packages and to mold the sensor device itself leaving only the sensing area exposed in the cavity.

Unisem continues to make MEMS packaging a key component to its growth moving forward with continued investments in technology, equipment and factory floor space to meet their demands as they move into their next billion units of MEMS devices assembled.

About Unisem

Unisem is a global provider of semiconductor assembly and test (OSAT) services for many of the world's most successful electronics companies. We offer an integrated suite of packaging and test services such as wafer bumping, wafer probing, wafer grinding; a wide range of leadframe and substrate IC packaging; wafer level CSP; and RF, analog, digital, and mixed signal test. Our turnkey services include design, assembly, test, failure analysis, and electrical, mechanical, and thermal characterization and modeling. The company has factory locations in Ipoh, Malaysia; Chengdu, People's Republic of China and Batam, Indonesia. Unisem is headquartered in Kuala Lumpur, Malaysia.

For additional information on Unisem, please visit: www.unisemgroup.com.