SEOUL, South Korea--(BUSINESS WIRE)--Samsung SDI (President and CEO: Cho Nam Seong) (KRX:006400) will start operating its Wuxi Plant in China where “PV paste,” a key photovoltaic material, will be produced.

On May 24, Samsung SDI announced that it will start operating a photovoltaic paste production line in its Wuxi Plant located in Jiangsu Province, China in June. In Samsung SDI’s Wuxi Plant, installation of a polarized film production line and a paste production line was concurrently started in September last year. The paste production line was recently completed, and thus will be put into operation first. Samsung SDI has set out a plant to start the operation in a scale of 40 tons a month and to increase the production scale up to 100 tons a month in the future.

Having established a system to respond immediately to the demands in China where more than 70% of global photovoltaic modular makers are located, it is forecasted that Samsung SDI’s marketing in China will further be accelerated. In addition, centering on the Wuxi Plant, Samsung SDI will expand its target markets to the Southeast Asian countries, such as Thailand, Malaysia and India, which are emerging as new photovoltaic markets recently.

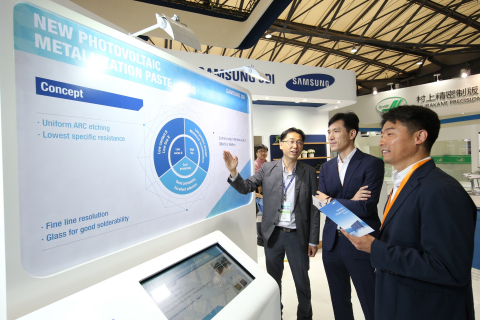

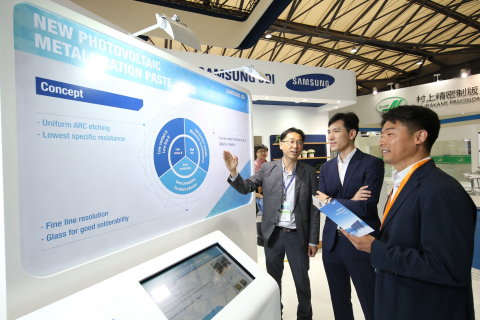

On May 24, Samsung SDI unveiled its new photovoltaic paste, “8800 Series” at the SNEC PV Power EXPO 2016. This is an international photovoltaic exhibition held in China, the largest photovoltaic market in the world.

* SNEC: Shanghai New International Expo Centre

* PV: Photovoltaic

SNEC PV Power EXPO, which is held from the 24th to the 26th in Shanghai, China, is the world’s largest solar cell exhibition where new photovoltaic products and services, such as manufacturing equipment, manufacturing technologies and materials, are introduced. In SNEC PV Power EXPO 2016, which is held for the tenth time this year, global major photovoltaic companies including Hanwha Q Cells, TrinaSolar and YingliSolar have set up their booths.

8800 Series, which Samsung SDI unveiled at the exhibition, is a product that delivers improved sunlight-to-electricity conversion efficiency. The conversion efficiency of solar cells developed so far is around 18 - 20% and the industry is strengthening technological development to improve the efficiency as much as possible.

Vice President Song Chang Lyong of Samsung SDI Electronic Materials Business Division said, “We have improved market responsiveness by starting Wuxi Plant operation and releasing new products that are applied to high-efficiency solar cells.” He added, “With this, we will advance to a true leader in the global photovoltaic market.”

In 2010, Samsung SDI started solar cell paste business based on its PDP electrode material technology with which it was leading the global market. Last year, entering its sixth year of solar cell paste business, Samsung SDI recorded the highest market share in China, the world’s largest solar cell market. This year, Samsung SDI plans to secure the top position in the global market by developing new products centering on its production base in China.

New Energy Finance, a market surveyor, forecasts that the global photovoltaic market will grow by an annual average of 9% or higher from 56GW in 2015 to 85GW in 2020. Accordingly, the markets for poly-silicon and PV paste, the key solar cell materials, are also expected to expand continuously.

* GW: GigaWatt, same as one billion watts

[What is PV paste?]

PV

paste is applied in a thin checkerboard-shaped layer to the surface

of a solar cell. Its role is to convert photovoltaic energy to

electricity. Comparing it to a leaf, which photosynthesizes, PV paste is

an electrode material that functions as a “vein” in the leaf. The amount

of solar energy received by a solar cell and converted into electricity

depends on the paste performance. Therefore, it is regarded as a key

material in a solar cell.