TOCHIGI, Japan--(BUSINESS WIRE)--Through joint development with Shirogane Co. Ltd (Head Office: Nasukarasuyama-shi, Tochigi-ken, Japan; President: Motoyoshi Ijichi), Metal and Technology Inc. (Head Office: Nasukarasuyama-shi, Tochigi-ken, Japan; President: Shuichi Ito) has successfully added carbon particles to an aluminum/copper alloy and homogeneously dispersed these carbon particles within the aluminum/copper alloy, an act that has conventionally been very difficult. This new material has been confirmed to change to microscopic crystal structures and can be expected to provide dramatic improvements to mechanical strength. As of the time of writing, both companies have made a joint application for a patent for "an aluminum/copper alloy with carbon additives." Moving forward, we shall perform research and development to introduce this "aluminum/copper alloy material with carbon additives" to the market. This research project was selected for the "2015 Strategic Foundational Technology Improvement Support Operation," for which the Government and The Small and Medium Enterprise Agency of Japan made public invitation.

[Background of the development of the "aluminum/copper alloy material with carbon additives"]

- Efforts to improve mechanical strength by way of changing to microscopic crystal structures

Generally speaking, the smaller the alloy crystal grain, the higher the metal material strength, with the strength rising in an inverse proportional manner to the crystal grain diameter to the power of 1/2. This is known as the Hall-Petch law. Therefore, there have been active efforts to improve mechanical strength by making crystal structures microscopic even in the field of nonferrous metals such as aluminum alloys.

Conventionally, it has been difficult to add carbon to nonferrous metals other than iron. However, by making use of the metal refinement know-how of Shirogane Co. Ltd that they have developed over a period of more than 30 years, we have successfully added carbon to lead-free solder alloys and pure copper. This has enabled us to improve mechanical strength by making crystal structures microscopic, and we have obtained a patent due to this result. These research projects were performed with University of Tsukuba as cooperative projects between the industry and academic fields. Furthermore, we also received assistance for the patent application costs from the Japan Science and Technology Agency, an auxiliary organization of the Japanese government's Ministry of Education, Culture, Sports, Science and Technology.

By focusing on the technology of Shirogane Co. Ltd for adding carbon to nonferrous metals, jointly developing this technology, adding carbon particles to an aluminum/copper alloy material, and homogeneously dispersing these carbon particles within the aluminum/copper alloy material, Metal and Technology Inc. has successfully made crystal structures microscopic, which has made it possible to improve mechanical strength as a material for practical use.

[Characteristics of the "aluminum/copper alloy with carbon additives"]

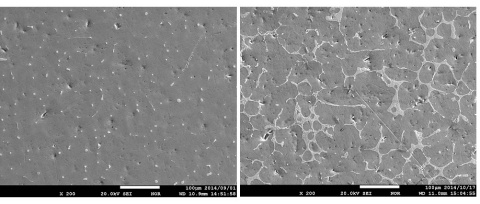

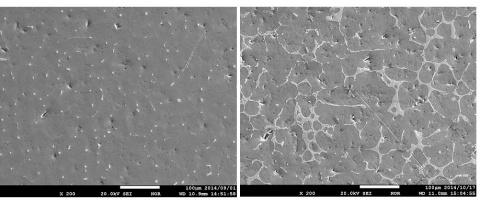

- Observation of the crystal structures of alloys of Al-5wt.%Cu and Al-5wt.%Cu+0.3wt.%C using a scanning electron microscope (SEM)

In order to investigate the differences in the crystal structures of an alloy of Al-5wt.%Cu with no added carbon and an alloy of Al-5wt.%Cu+0.3wt.%C with added carbon, observations were performed with an electron probe microanalyzer (EPMA). Figure 1 (a) is a photograph obtained from the alloy of Al-5wt.%Cu with no added carbon and Figure 1 (b) is a photograph obtained from the alloy of Al-5wt.%Cu+0.3wt.%C with added carbon. Comparing these photographs, the whitish area representing the eutectic phase is larger in (b), which confirms that the structure in (b) has been made microscopic.

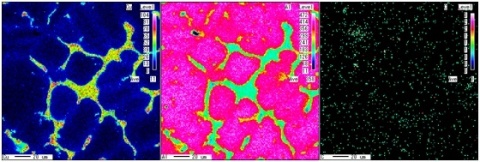

- Mechanism of the crystal structure of the aluminum/copper alloy with carbon additives

An X-ray microanalyzer (XMA) was used to investigate the distribution of the chemical elements in the Al-5wt.%Cu+0.3wt.%C alloy material with carbon additives shown in Figure 1 (b). Figure 2 (a), (b), and (c) show color mapping images of the positions and amounts of the chemical elements of copper (Cu), aluminum (Al), and carbon (C), respectively. From Figure 2 (C), we could observe that carbon has dispersed homogeneously within the entire structure. It is hypothesized that the carbon impedes the growth of the alloy's crystal structure and thereby makes the crystal structure microscopic.

* For electron microscope photographs of other aluminum/copper alloys

with carbon additives, see the following URL.

http://metal-techno.jp/english/alloys/

- Mechanical strength of the aluminum/copper alloy with carbon additives

To investigate the change in mechanical strength in the aluminum/copper alloy due to the addition of carbon, a tensile strength testing instrument was used to measure the tensile stress. The result was that the tensile strength of the aluminum/copper alloy with carbon additives was improved over the alloy without carbon. This improved tensile strength depends on the amount of carbon added and the heat treatment temperature condition, but a tensile strength at least twice that of the alloy without carbon was obtained, which indicates that the aluminum/copper alloy with carbon additives can be used as a material for practical use.

[Expected application scope of the "aluminum/copper alloy with carbon additives"]

Weight saving and high strengthening of metal materials is urgently necessary in order to meet societal needs such as energy conservation, resource conservation, and environmental friendliness. Also, efforts to make structural materials lightweight by increasing their hardness are being carried out in fields for transport machinery such as automobiles and railway vehicles. Metal and Technology Inc. is aiming to contribute to efforts to make the structural materials of automobiles, railway vehicles, and ships more lightweight and stronger by making use of the characteristics of high strength and high extensibility of the "aluminum/copper alloy material with carbon additives" that we have developed. We are currently planning to perform joint research together with a prominent Japanese manufacturer related to aluminum with the goal of making this alloy into a marketable product. Going forward, we are planning to search for international companies related to aluminum to cooperate with and to accelerate the progress of the processes of research, development, and making into a marketable product.

About Metal and Technology Inc.

- Trade Name: Metal and Technology

-

Executives:

President: Shuichi Ito

Director: Motoyoshi Ijichi (President of Shirogane Co. Ltd)

Board Member and Technical Advisor: Kenichi Oshima (Professor Emeritus of University of Tsukuba) -

Addresses:

Head Office: 1-5-32, Chuo, Nasukarasuyama-shi, Tochigi-ken, Japan

Tokyo Office: 301 First Real Tower Shinjuku, 7-5-9 Nishi Shinjuku, Shinjuku-ku, Tokyo, Japan - Establishment: July 2009

- Website: http://metal-techno.jp/english/

About Shirogane Co. Ltd

- Trade Name: Shirogane

-

Executive:

President: Motoyoshi Ijichi - Address: 1-5-32 Chuo, Nasukarasuyama-shi, Tochigi-ken, Japan

- Establishment: December 1985