OSAKA, Japan--(BUSINESS WIRE)--Panasonic Corporation today announced that it will start mass production of polybutylene terephthalate (PBT) molding compounds for laser welding in March, 2016, a move that will contribute to the enhancement of long-term reliability and the flexibility of design of automotive switches and sensors.

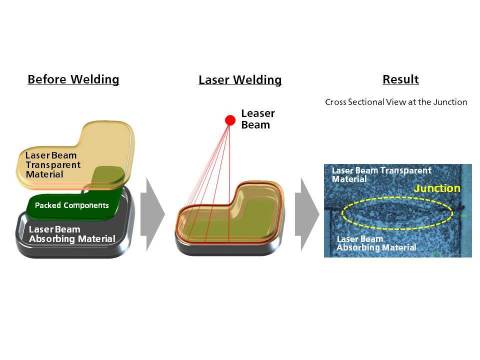

Currently, processing methods including sealing with packings and bolts, bonding with adhesive agents, as well as ultrasonic welding, are used for the production of automotive sensors. Instead of such processing methods, laser welding has recently attracted the industry’s attention as its high welding strength can shorten the bonding time and increase productivity. However, plastic molding compounds generally used for laser welding have had low laser transmittance, leading to problems with welding strength and waterproof properties. In order to solve these problems, we have commercialized the PBT molding compounds with the industry’s highest*1 laser transmittance; they excel in their welding strength and waterproof properties. With these compounds, it is possible to use laser welding instead of the current processing methods, and therefore long-term reliability and the flexibility of design can be enhanced when they are applied to automotive components.

These molding compounds have the following features:

1. The

industry’s highest*1 laser transmittance, which enables a

high welding strength and contributes to the long-term reliability of

automotive components.

- Laser transmittance: 72 % (52 % for our conventional products*2)

- No air leak was found under the air pressure (3 atm) in water after a high temperature high humidity storage test*3 or a temperature cycling test*4.

2. Stable quality and performance are ensured with low warpage of molded parts, and this contributes to the enhancement of the flexibility of design of automotive components.

- Warpage: 0.5 mm or less (2.3 mm for our conventional products*2, 1/4 of the conventional products)

3. Excellent hydrolysis resistance enables the water resistance required for small to large automotive components.

- High strength retention rate after a high temperature high humidity storage test*3: 94% (50% for our conventional products*2)

*1: As of February 12, 2016 for PBT molding materials for laser welding

(according to Panasonic data)

*2: Our conventional PBT molding

compounds

*3: After 1,000 hours under the temperature of 85℃ and

humidity of 85%

*4: Temperature range: -40℃–100℃

The molding compounds will be exhibited at the followings shows:

- The LED Show (March 1–3, 2016, Santa Clara, CA)

- Highly-Functional Material World 2016 (April 6–8, 2016, Tokyo Big Sight)

About Panasonic

Panasonic Corporation is a worldwide leader

in the development of diverse electronics technologies and solutions for

customers in the consumer electronics, housing, automotive, enterprise

solutions, and device industries. Since its founding in 1918, the

company has expanded globally and now operates 468 subsidiaries and 94

associated companies worldwide, recording consolidated net sales of

7.715 trillion yen for the year ended March 31, 2015. Committed to

pursuing new value through innovation across divisional lines, the

company uses its technologies to create a better life and a better world

for its customers. To learn more about Panasonic: http://www.panasonic.com/global.